More efficient plant operation with LESER Change-over Valves

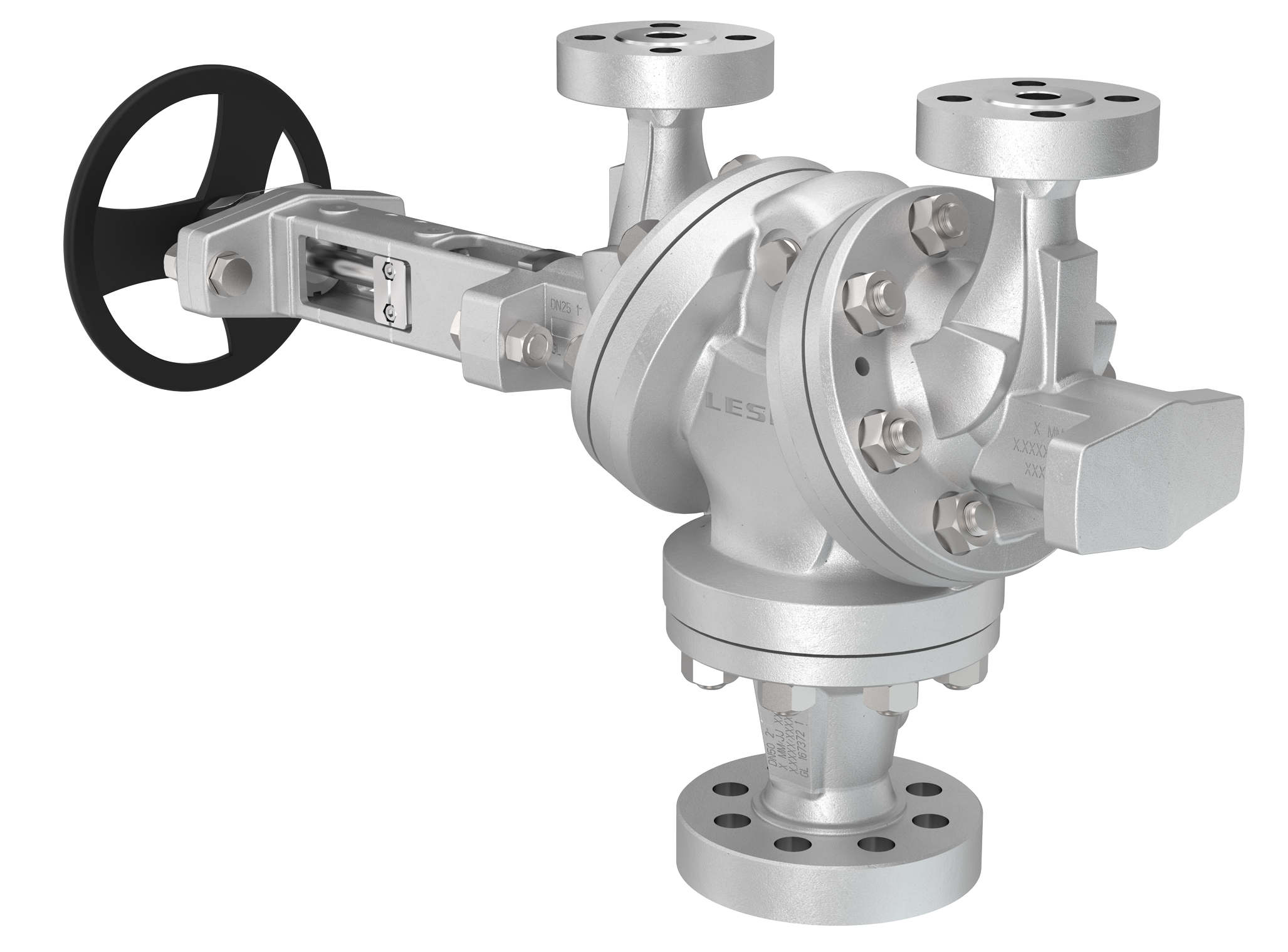

The LESER Change-over Valve Type 330 and 320 offers the solution for safe and efficient system availability 24/7. It is easy to operate and, in combination with safety valves, provides permanent protection for a permanently running system.

ARKEMA is operating its plant in a non-stop mode requiring a high level of availability of the equipments as utilities devices as compressed air tanks. To allow high availability of its plant, ARKEMA decided to go for LESER’s new Change-over Valves. For ARKEMA, quality and reliability are the most important decision criteria to decide on Safety Valves and Change-over Valves.