Contents (Click on the links to navigate)

The primary purpose of a safety valve is the protection of life, property and environment. A safety valve is designed to open and relieve excess pressure from vessels or equipment and to reclose and prevent the further release of fluid after normal conditions have been restored.

There is a number of reasons why the pressure in a vessel or system can exceed a predetermined limit. API Standard 521/ISO 23251 Sect. 4 provides a detailed guideline about causes of overpressure. The most common are:

Each of the above listed events may occur individually and separately from the other. They may also take place simultaneously. Each cause of overpressure also will create a different mass or volume flow to be discharged, e.g. small mass flow for thermal expansion and large mass flow in case of a chemical reaction. It is the user’s responsibility to determine a worst case scenario for the sizing and selection of a suitable pressure relief device.

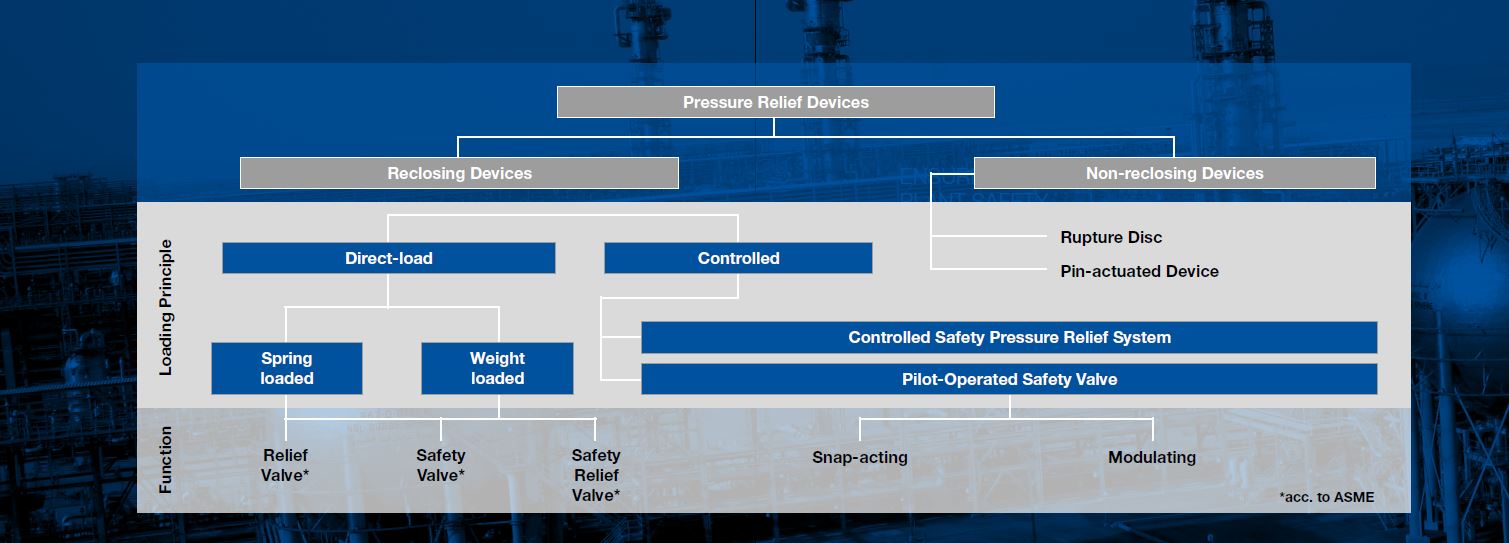

In the context of pressure relief devices, a fundamental distinction can be made between reclosing and non-reclosing devices. Safety valves are part of the reclosing devices and are differentiated on the basis of their loading principle or controllability.

In addition, a distinction can be made based on the function of the valves. Here, a distinction is made between relief valves (full lift), normal safety valves and proportional safety relief valves.

Notice for mobile users

Hold your smartphone horizontally to get the best possible view on the following visualization.

There are two main types of safety valves: Spring-loaded safety valves and pilot-operated safety valves. Also relevant are so-called change-over valves, which ensure continuous system availability (not included in the illustration)

The function und design of safety valves differs depending on the main type or loading principle. Use the following buttons to navigate to the respective main type pages. There you will find the corresponding LESER safety valves as well as further information, for example on the function and design of the main types.

In order to ensure the greatest possible plant safety, the analysis of the conditions and requirements of an application and the corresponding dimensioning of a safety valve is crucial. Determining the necessary dimensions and flow cross-section of a safety valve is referred to as "sizing the safety valve". Numerous parameters are taken into account in this calculation.

Examples of relevant substance data:

Examples of relevant operating data:

For the sizing of safety valves LESER has developed its own free software VALVESTAR®. You can access the tool via the following link.

The main types of safety valves are identified by symbols. Therefore, there is not only one, but several safety valve and safety valve symbols. They are often shown on safety valves or their packaging. In addition, they are used in technical drawings and schematics as well as system sketches - for example, in the description of DIN standards.

The following symbols are related with the main types of safety valves:

Spring-loaded Safety Valves and Pilot-operated Safety Valves

Spring-loaded Safety Valves and Pilot-operated Safety Valves

What is a safety valve used for?

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

How does a safety valve work?

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

What is the set pressure of a safety valve?

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.Your local contact person will support you with all questions concerning the safety valve.