Safety and reliability in a diverse industry

There are many different types of plants in the chemical industry, which forms the backbone of our industrialized world. Plants for polymers, fertilizers, soaps or cleaning agents; production in bulk, batches or continuous; different units for the process medium, steam, cooling or heating are increasing the requirements in quantity and diversity.

Hence, a partner is needed who provides the required wide product range, technical expertise and the ability to integrate into the growing supply chains.

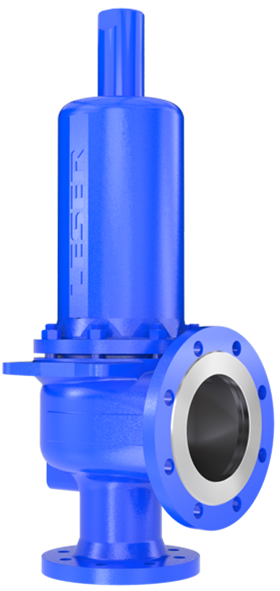

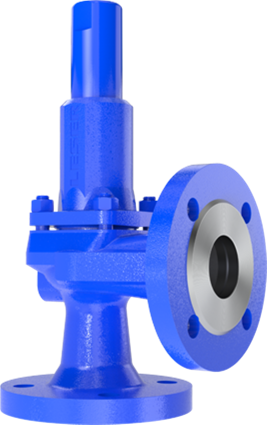

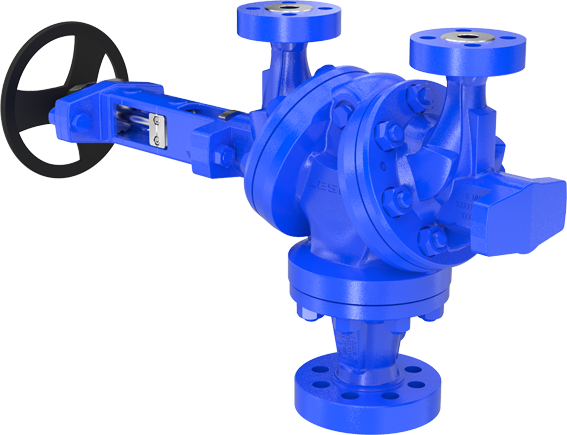

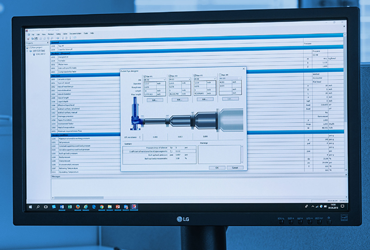

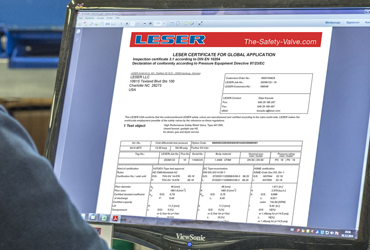

LESER is the supplier of safety valves covering all applications and regulations. Type 441 of the product group High Performance is the standard safety valve for the chemical industry. The product group Critical Service is designed for highly corrosive media such as chlorine. Modulate Action safety valves minimize media loss. In addition, LESER increases the availability of your plant with the change-over valves from the Best Availability product group.