Mr. Heppner, in which area are pilot-operated safety valves used?

Paraffin is produced in the plant area in which we serviced the valves.

Why did you decide to use POSV here?

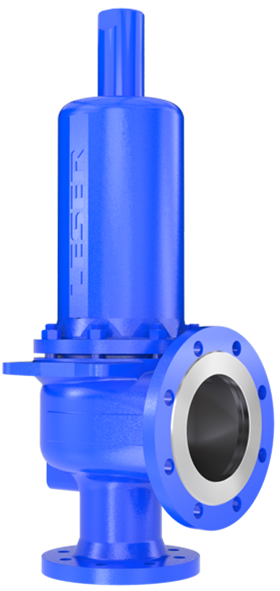

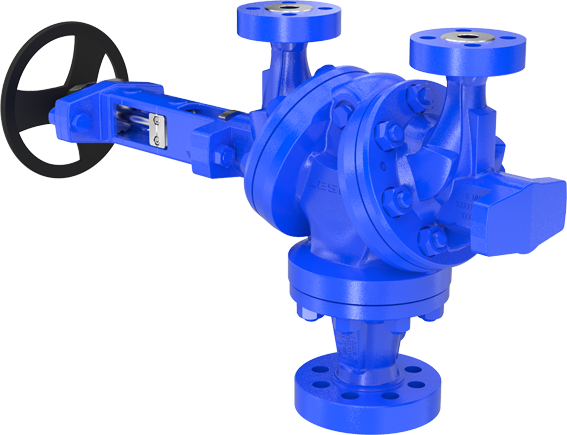

The pilot-operated safety valves were selected for several reasons. The operating pressure of the system is very close to the set pressure of the safety valve. A POSV is ideal for this because this type of construction is tight until it is activated.

In addition, there is a high backpressure of up to 65% of the set pressure in the blow-off system if the valve should open. This value is above the admissible value for spring-loaded safety valves. Pilot-operated safety valves, on the other hand, operate up to 70% of the set pressure. On the other hand, the supply lines to the safety valves are very long. This can lead to an inlet pressure loss of more than three percent when the valves are activated.

LESER has solved the problem with a separate pressure tapping line. The piping is routed directly from the container to be protected to the pilot valve of the POSV. The supply lines for pressure tapping are now between 10 and 20 m long. At this point, it becomes clear that the planners have done their homework. The system was designed properly and yet efficiently.

What does maintenance really depend on?

The maintenance of a system must be carried out carefully by trained personnel in accordance with the manufacturer’s specifications, so that production can then run smoothly again. In addition, the maintenance time should be very short, because the maintenance of safety valves means costly plant downtimes.

Etabo was commissioned by the operator of the Lingen refinery, BP Europa SE, to service LESER’s pilot-operated safety valves as part of a normal maintenance cycle.

What did you notice during the maintenance of the pilot-operated safety valves?

We were very surprised about the good condition of the safety valves.

From the inside, they looked as if they had just been installed. With the exception of the main valve, all components in direct contact with the media were made of stainless steel and showed little tendency to corrosion. We know this from other valves of this type in a different way - but with the same service life.

Only the seals showed slight wear after four years of operation. We therefore only had to replace the FKM O-rings, as is also stated in the maintenance recommendation. The LESER spare parts kit contained everything we needed. In addition, LESER’s valves are very precisely manufactured, so we were quick to complete the maintenance.

What is your conclusion?

As a certified service partner of LESER, we know and appreciate the uncomplicated cooperation and high quality of the safety valves. As this maintenance shows, the components were in very good condition. The spare parts kits for the POSV enable very simple and cost-effective repairs.

The combination of all these factors makes our daily work easier and enables us to carry out maintenance accordingly quickly. And the shorter the maintenance time, the better for our customers, the plant operators. In this respect, LESER helps us to ensure a high level of customer satisfaction.