The challenge

The ARKEMA company operates its plant in non-stop mode, which requires high availability of the connected supply equipment, such as tanks with compressed air. To ensure high availability of the plant, ARKEMA opted for the new change-over valves from LESER .

Why did the customer choose LESER products ?

For ARKEMA, quality and reliability are the most important decision criteria when choosing Safetys and Change-over valves .

More efficient plant operation with LESER change-over valves

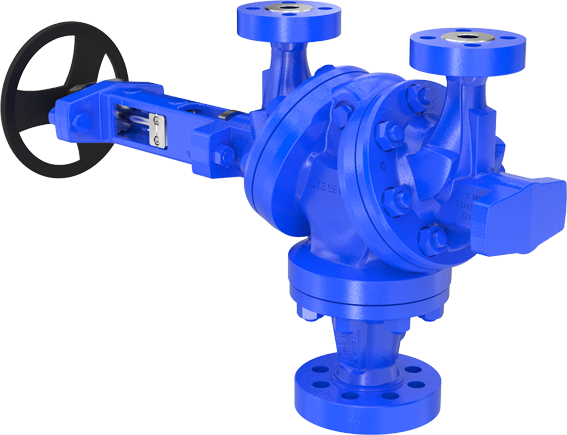

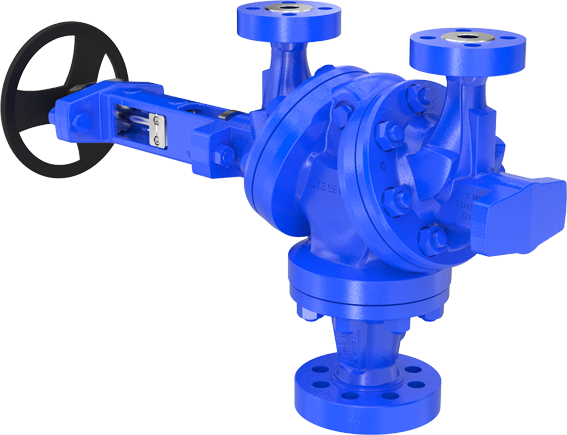

The LESER change-over valve of the type n 330 and 320 offers the solution for safe and efficient plant availability 24 / 7. It is easy to operate and, in combination with Safetys valves , provides permanent protection for a permanently running plant.

Flow tests and computational fluid dynamics (CFD) simulations were used to develop a flow-optimized design with minimal pressure loss.

Each configuration of these change-over valves has a specific resistance coefficient that allows reliable and precise calculation of the inlet pressure drop .

Due to their durable design, these new change-over valves are maintenance-free and tested through endurance trials. They are the economical solution because a suitable selection can be made for every application .

About the customer

ARKEMA is one of the world's leading manufacturers of hydrogen peroxide. Hydrogen peroxide (H2O2) is used in various concentrations as an example for the sterilization of food packaging. The Shanghai plant was established in 2000 and expanded in 2008.