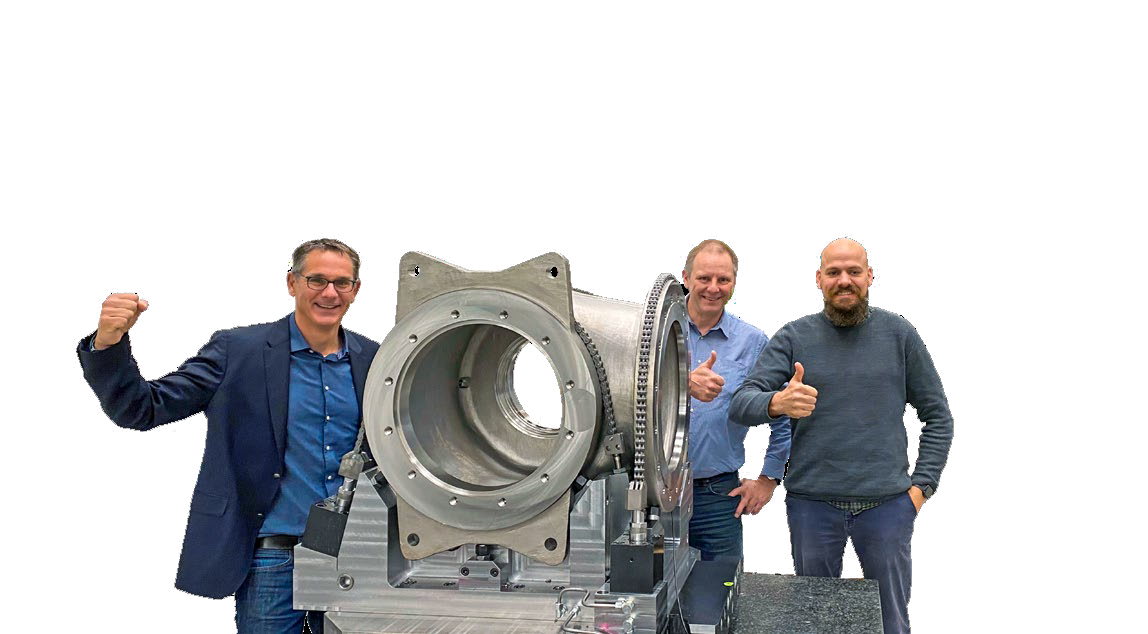

“Think BIG”: An XXL investment

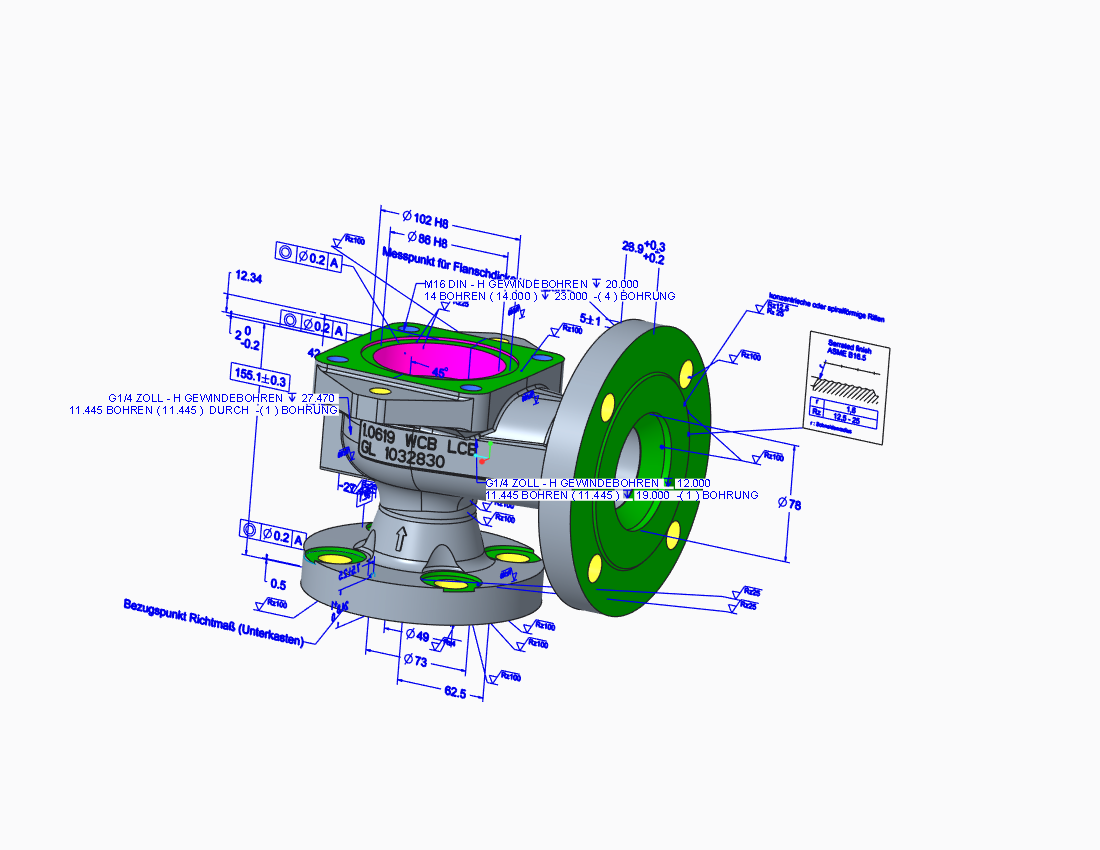

The new manufacturing technology for very large safety valves is the largest single investment in the history of the site. It shortens the delivery times of Type 441 safety valves from DN 250 / 10 inches on upwards.