LESER sets the standard in product development

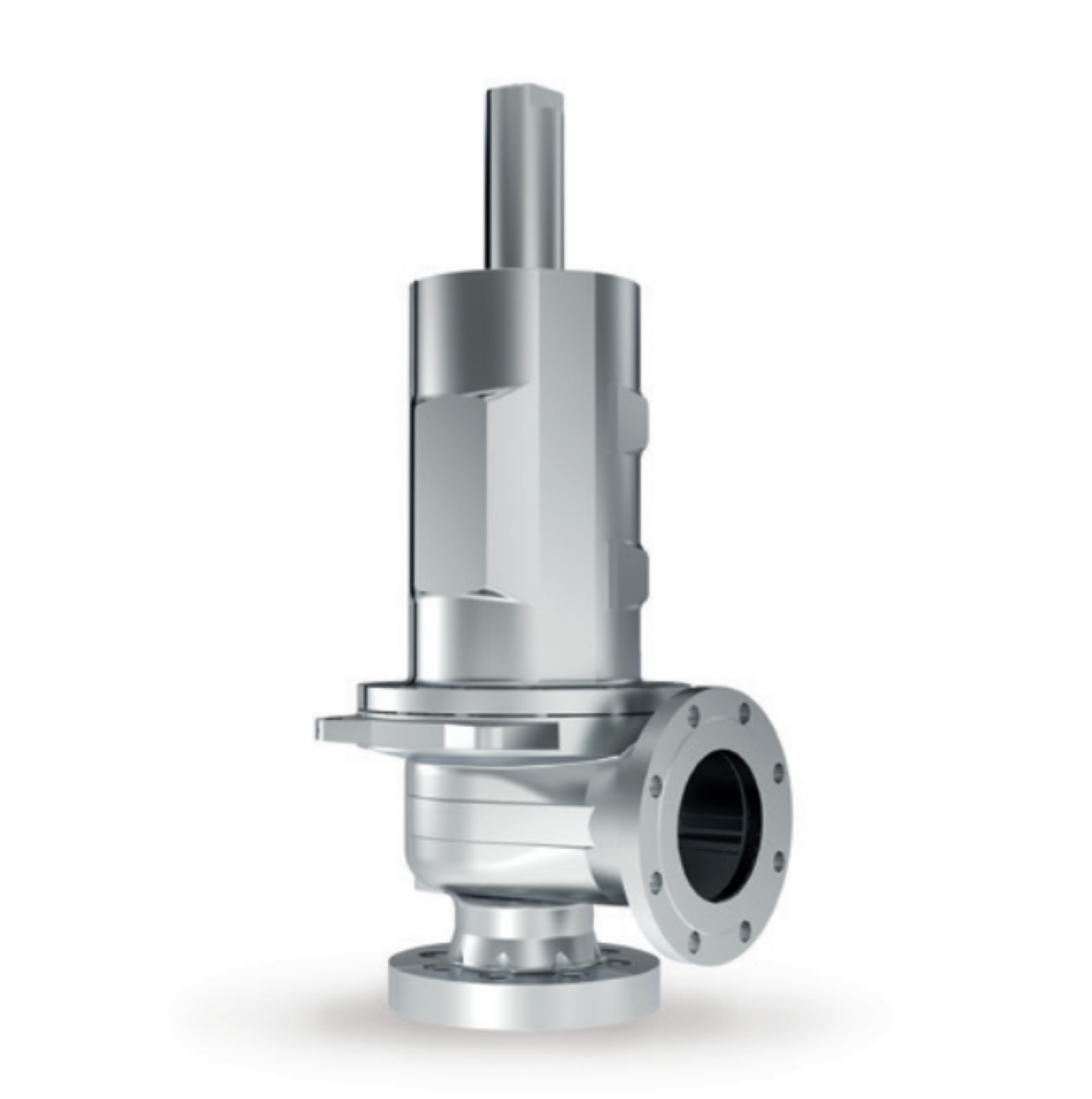

What requirements do you as a user have for safety valves? Your needs as a customer are the basis for all our product development. Together with you, LESER finds solutions.

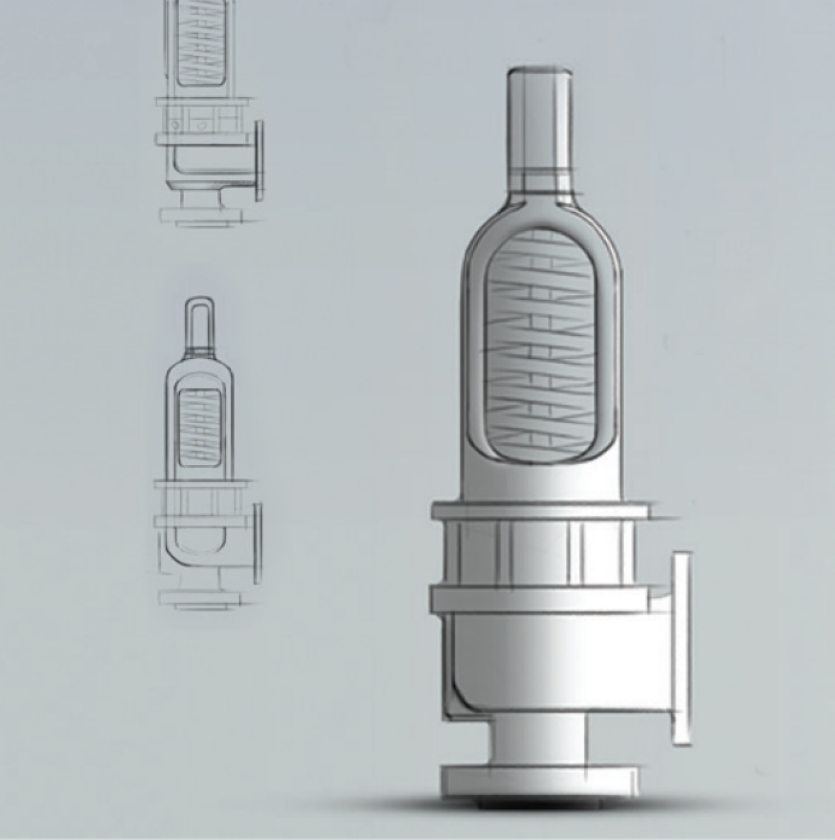

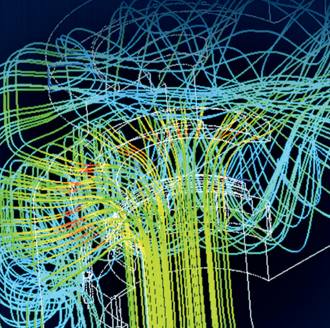

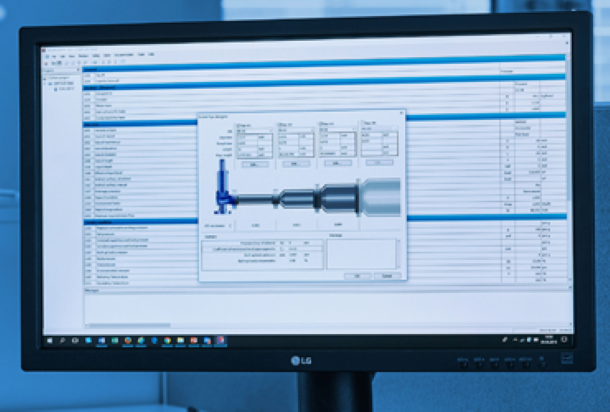

During development, LESER couples existing empirical development methods with computer-aided tools such as computational modeling and simulations. Through this, our engineers achieve such significant improvements as:

- In-depth theoretical understanding of complex operational interrelationships

- Theoretical definitions of optimal geometries in relation to influencing factors

However, even the best simulation has to be checked against its assumptions. That is why LESER tests at its own test labs and under real conditions before a new product is delivered to you.