Continuing the Fourth Industrial Revolution with the Digital Twin

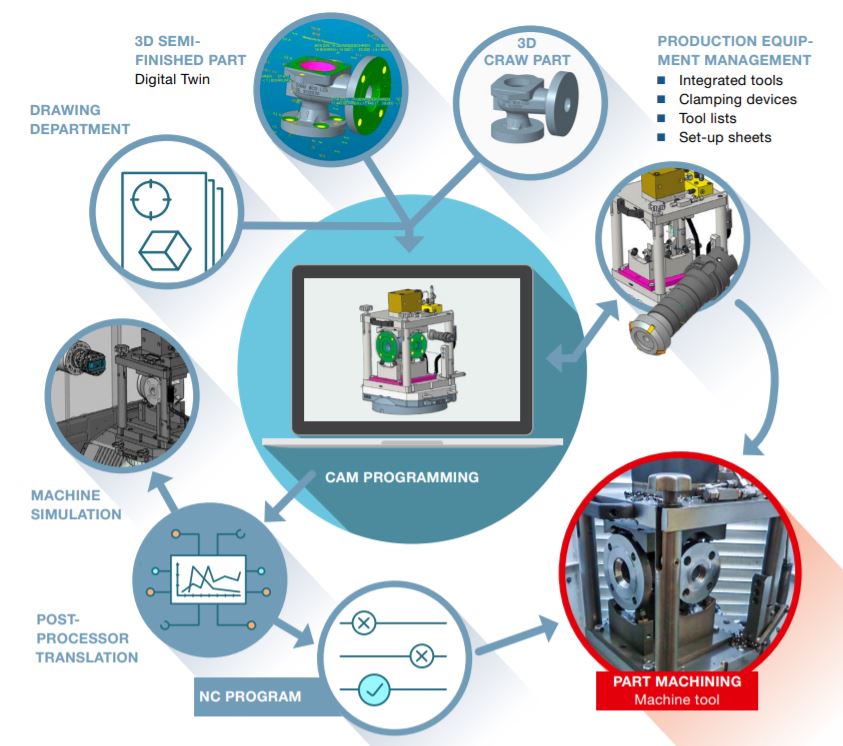

Computer-aided design and computer-aided manufacturing (CAD/CAM) are merging the design and production processes at LESER into a single workflow.

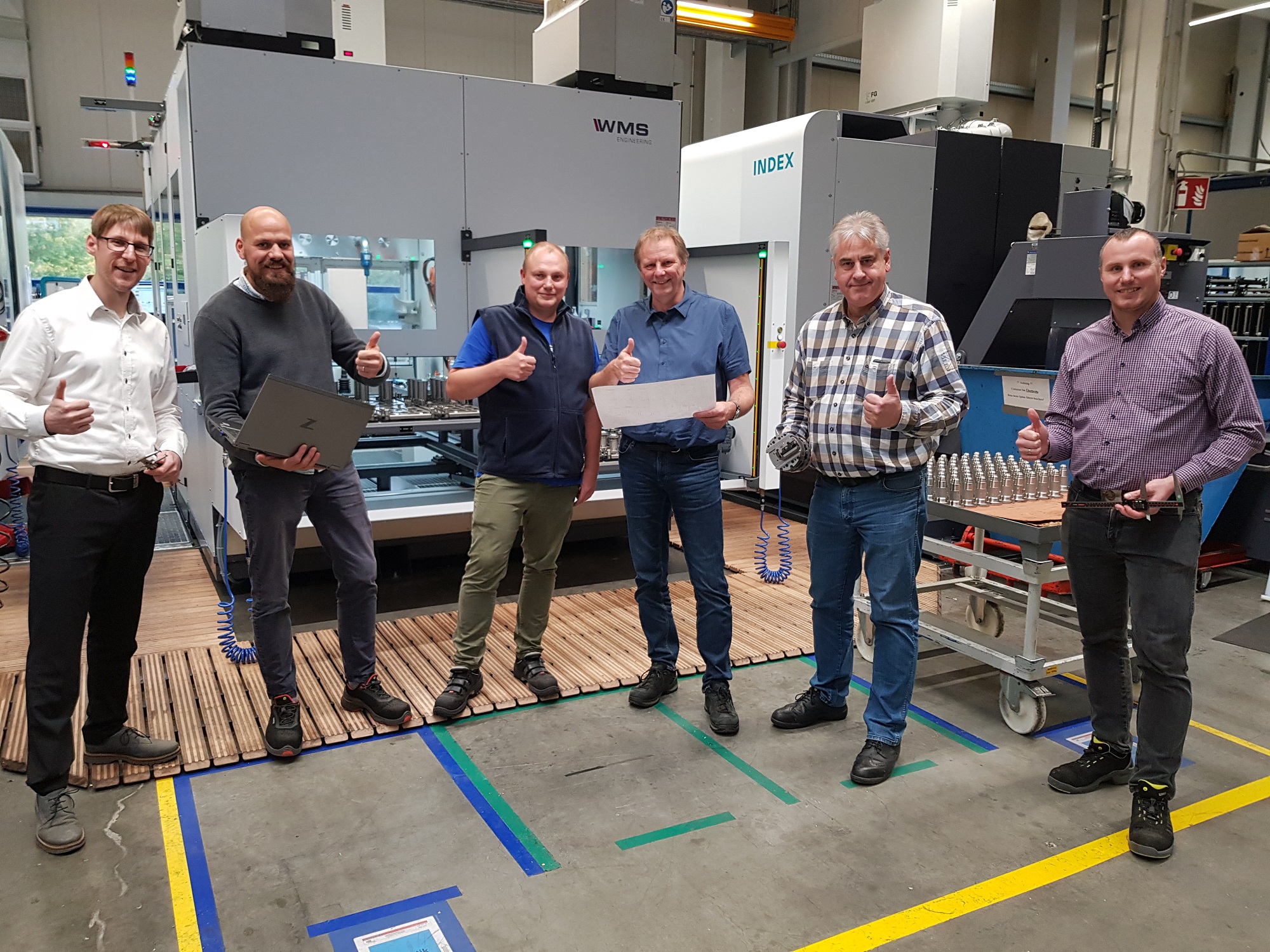

Over the past decade or so, the German term “Industrie 4.0” has become a synonym for the Fourth Industrial Revolution, which is in full swing at LESER where the focus of digitalization is on transforming manufacturing processes. But the changes the digital transformation brings about have repercussions far beyond the way the shop floor is organized: For successful digitalization it is essential to integrate all design, production and planning systems.

This is why LESER has begun to implement computerbased programming of its complex, automated CNC-controlled machining equipment within the scope of the “LESER is digital” program. This includes full 3D modelling of each component or product as a “digital twin”. These activities are enabled by Computer Aided Design (CAD) and Computer-Aided Manufacturing (CAM).