Contents (Click on the links to navigate)

There are two main types of safety valves: Spring-loaded safety valves and pilot-operated safety valves / safety valves. Also relevant are so-called change-over valves, which ensure continuous system availability.

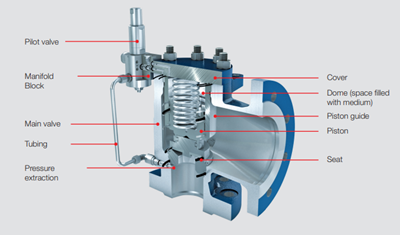

Pilot operated safety valves (POSV = “pilot operated safety valves”) are controlled by the process medium in which they operate. To achieve this, system pressure is fed to the pilot valve (= control component for the main valve) via the pressure tapping line. To enable this, the system pressure is transferred to the pilot valve via the pressure tapping line. The pilot valve uses the space in the dome above the main valve piston to open and close the main valve.

Pilot operated safety valves are controlled by the process medium in which they operate. To achieve this, system pressure is fed to the pilot valve (= control component for the main valve) via the pressure tapping line which uses the space in the dome above the main valve piston to open and close the main valve.

The terms "pilot-operated safety valve" and "pilot valve" are often mistakenly used synonymously. The pilot-operates safety valve is the entire safety valve, which includes the pilot valve as well as the main valve.

The pilot valve, also called the “pilot”, is the control unit of the pilot-operated safety valve. It controls the function and behavior of the main valve.

During normal operation, the system pressure is picked up at the main valve inlet and routed to the dome (see illustration).

Since the dome area is larger than the area of the main valve seat, the closing force is greater than the opening force. This keeps the main valve tightly closed.

2. At set pressure: Actuating state

At set pressure, the pilot valve actuates. The medium is no longer routed to the dome (see illustration). This prevents a further rise in dome pressure.

Also, the dome is vented. As a result, the closing force ceases as a precondition for the system overpressure to push the main valve open.

The main valve opens. Depending on the design of the pilot valve, this opening is either rapid and complete (Pop Action) or gradual and partial following system pressure (Modulate Action).

If system pressure drops to closing pressure, the pilot valve actuates and again routes the medium to the dome.

The pressure in the dome builds up and the main valve recloses either rapidly and completely (Pop Action) or gradually and partially following system pressure (Modulate Action).

There are two types of pilot-operated safety valves, and their difference is evident by their opening and closing

In the case of abrupt behavior, a so-called pop action pilot is used. With this, the pressure from the dome is completely diverted to the outside. The main valve opens completely.

Advantages of Pop Action Valves

In the case of modulating behavior, a so-called Modulate Action Pilot is used. In this case, the dome is only partially relieved. The degree of relief is determined by the pressure on the inlet side, which causes the pilot to relieve the pressure. In this way, the main valve adjusts to partial strokes and discharges only the exact amount of process medium required.

Advantages of Modulating Valves

What is a Pilot-operated Safety valve?

Pilot operated safety valves are controlled by the process medium in which they operate. To achieve this, system pressure is fed to the pilot valve (= control component for the main valve) via the pressure tapping line which uses the space in the dome above the main valve piston to open and close the main valve.

What is a pilot valve?

The pilot valve, also called the “pilot”, is the control unit of the pilot-operated safety valve. It controls the function and behavior of the main valve.