There are two main types of safety valves: Spring-loaded safety valves and pilot-operated safety valves. Also relevant are so-called change-over valves, which ensure continuous system availability.

Spring-loaded safety valves are one of the main types of safety valves in which the closing force or spring force is applied by a spiral spring.

Valve closed

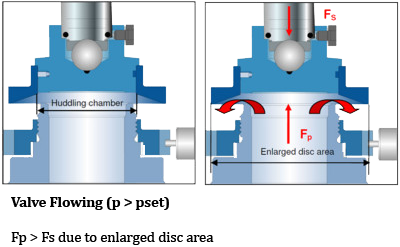

In a direct spring loaded safety valve the closing force or spring force is applied by a helical spring which is compressed by an adjusting screw. The spring force is transferred via the spindle onto the disc. The disc seals against the nozzle as long as the spring force is larger than the force created by the pressure at the inlet of the valve. The figure shows the enlarged nozzle and disc area of a safety valve with the forces acting on the disc.

Valve opening

In an upset situation a safety valve will open at a predetermined set pressure. The spring force Fs is acting in closing direction and Fp, the force created by the pressure at the inlet of the safety valve, is acting in opening direction. At set pressure the forces Fs and Fp are balanced. There is no resulting force to keep the disc down on the seat. The safety valve will visibly or audibly start to leak (initial audible discharge).

The pressure below the valve must increase above the set pressure before the safety valve reaches a noticeable lift. As a result of the restriction of flow between the disc and the adjusting ring, pressure builds up in the huddling chamber. The pressure now acts on an enlarged disc area. This increases the force Fp so that the additional spring force required to further compress the spring is overcome. The valve will open rapidly with a "pop", in most cases to its full lift.

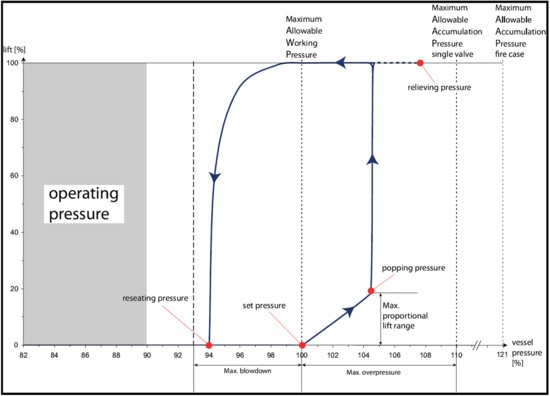

Overpressure is the pressure increase above the set pressure necessary for the safety valve to achieve full lift and capacity. The overpressure is usually expressed as a percentage of the set pressure. Codes and standards provide limits for the maximum overpressure. A typical value is 10%, ranging between 3% and 21% depending on the code and application.

Valve

reclosing

In most applications a properly sized safety valve will decrease the pressure in the vessel when discharging. The pressure in the vessel will decrease at any subsequent point, but not later than the end of the upset situation. A decreasing pressure in the vessel will lower the force Fp. At set pressure however the flow is still acting on the enlarged disc area, which will keep the valve open. A further reduction in pressure is required until the spring force Fs is again greater than Fp and the safety valve begins to reclose. At the reseating pressure the disc will touch the nozzle again and the safety valve recloses.

Blowdown is the difference between set pressure and reseating pressure of a safety valve expressed as a percentage of set pressure. Typical blowdown values as defined in codes and standards are -7% and -10%, ranging from -4% to -20% depending on the code and service (steam, gas or liquid).

The following diagram shows a typical functional curve of a spring loaded safety valve. It is important to understand that the operating pressure of the protected equipment should remain below the reseating pressure of the valve. Most manufacturers and codes and standards recommend a difference of 3 – 5% between reseating pressure and operating pressure to allow proper reseating of the valve and achieve good seat tightness again.

What is a spring-loaded safety

valve?

Spring-loaded safety valves are one of the main types of safety valves in which the closing force or spring force is applied by a spiral spring.

How does a spring-loaded safety

valve work?

Safety valves are designed to open and release excess pressure from vessels or equipment and then close again. Spring-loaded safety valves are one of the main types of safety valves in which the closing force or spring force is applied by a spiral spring.