The challenge:

As an internationally active OEM Aerzener Maschinenfabrik has to fulfill a multitude of local, legal requirements as well as customer specifications, e.g. of pressure equipment. Each region has its own set of regulations: For example, the Pressure Equipment Directive applies in Europe and the ASME Code in America. In addition to the general requirement for global approval concepts, e.g. for pressure equipment according to PED or ASME, the trend among companies is toward modular systems. Planners are trying to use small, interconnectable systems to be able to work flexibly and scalably. This makes it easier to coordinate plant capacities. This modularization considerably restricts the installation space and freedom in the design and development of compressors, for example.

In addition to the small footprint of compressors required above, it should be completely enclosed by a sound hood to reduce noise emissions. To reduce the size of the very

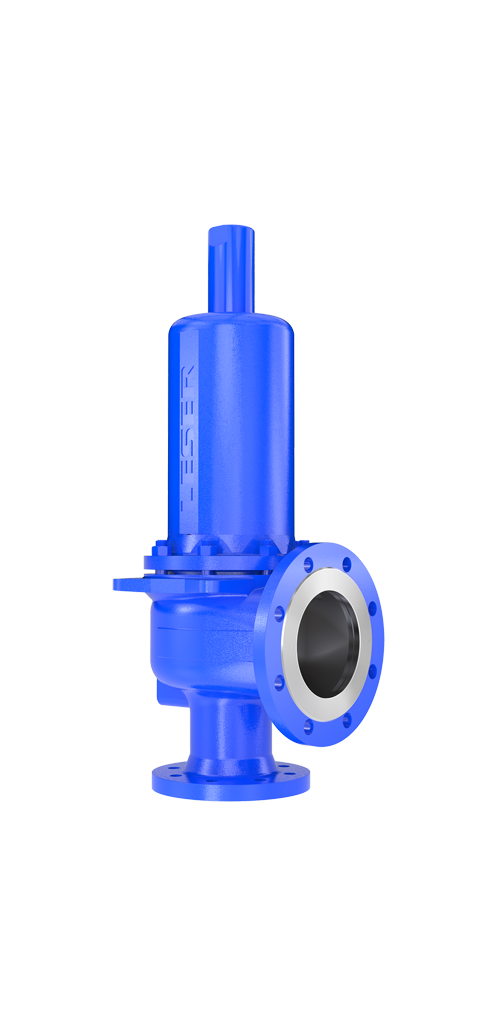

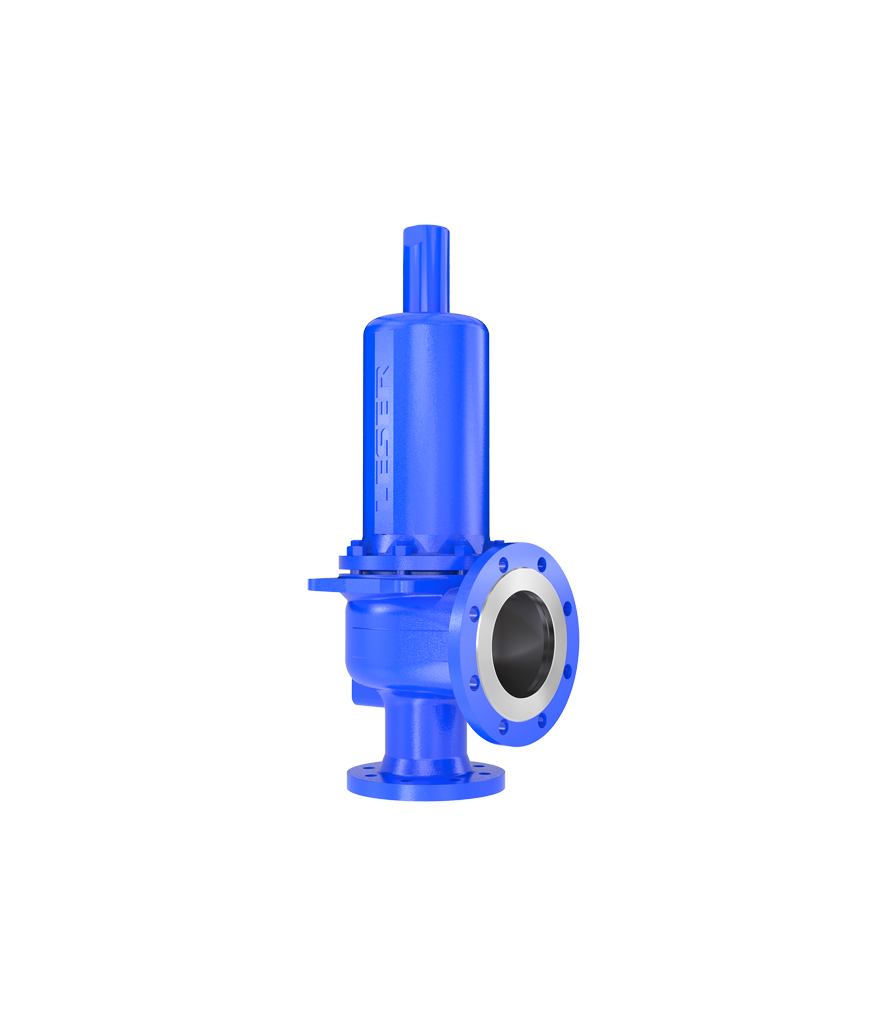

AERZEN requires special valves that are adapted to the small installation space available.

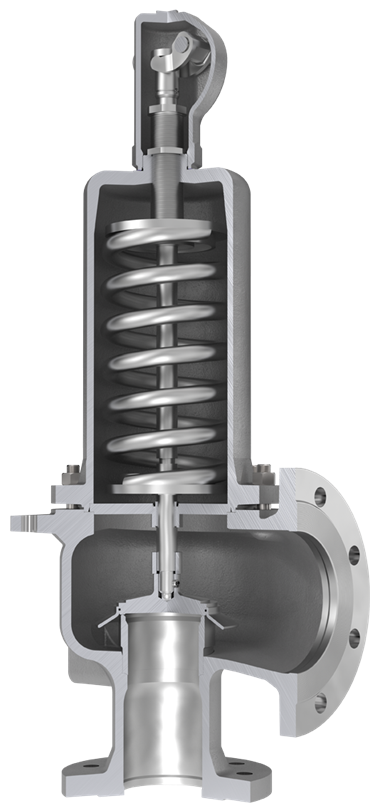

are. Compressors are discontinuous machines for generating pressure. To ensure that pulsations do not impair the function of the Safetys valve , the test pressure is set accordingly on the valve and an appropriate distance from the discharge line is ensured by design.

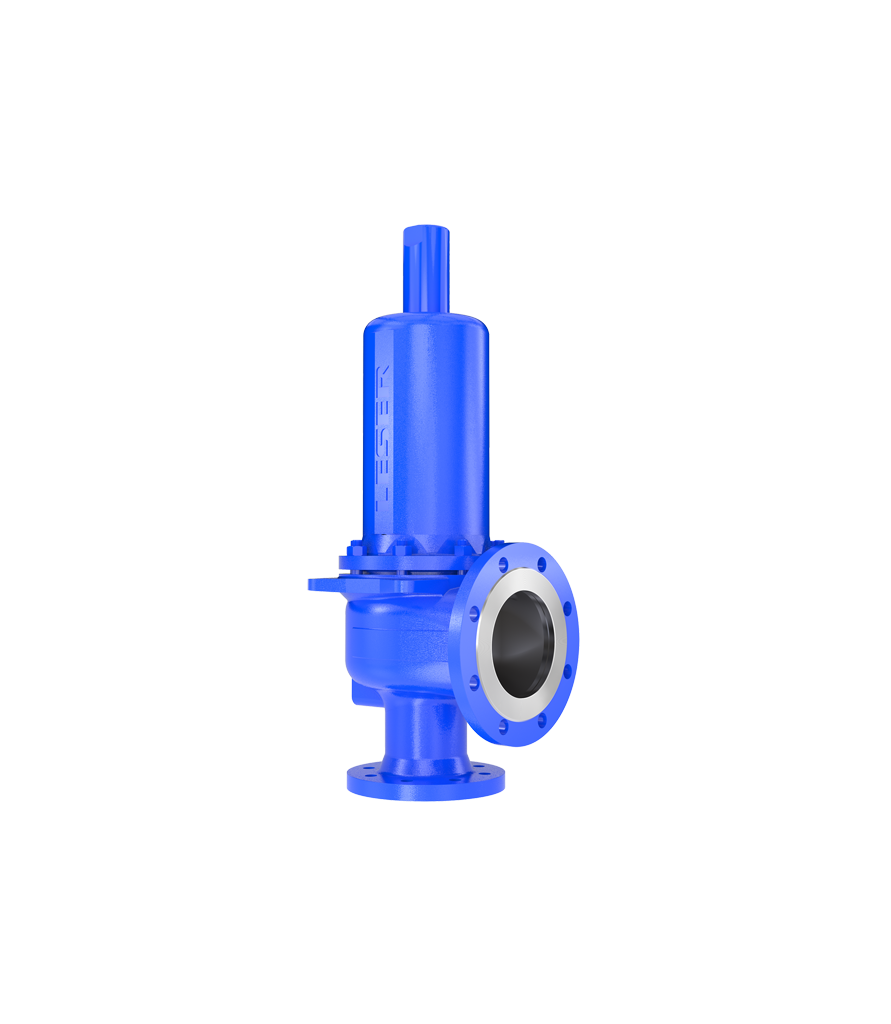

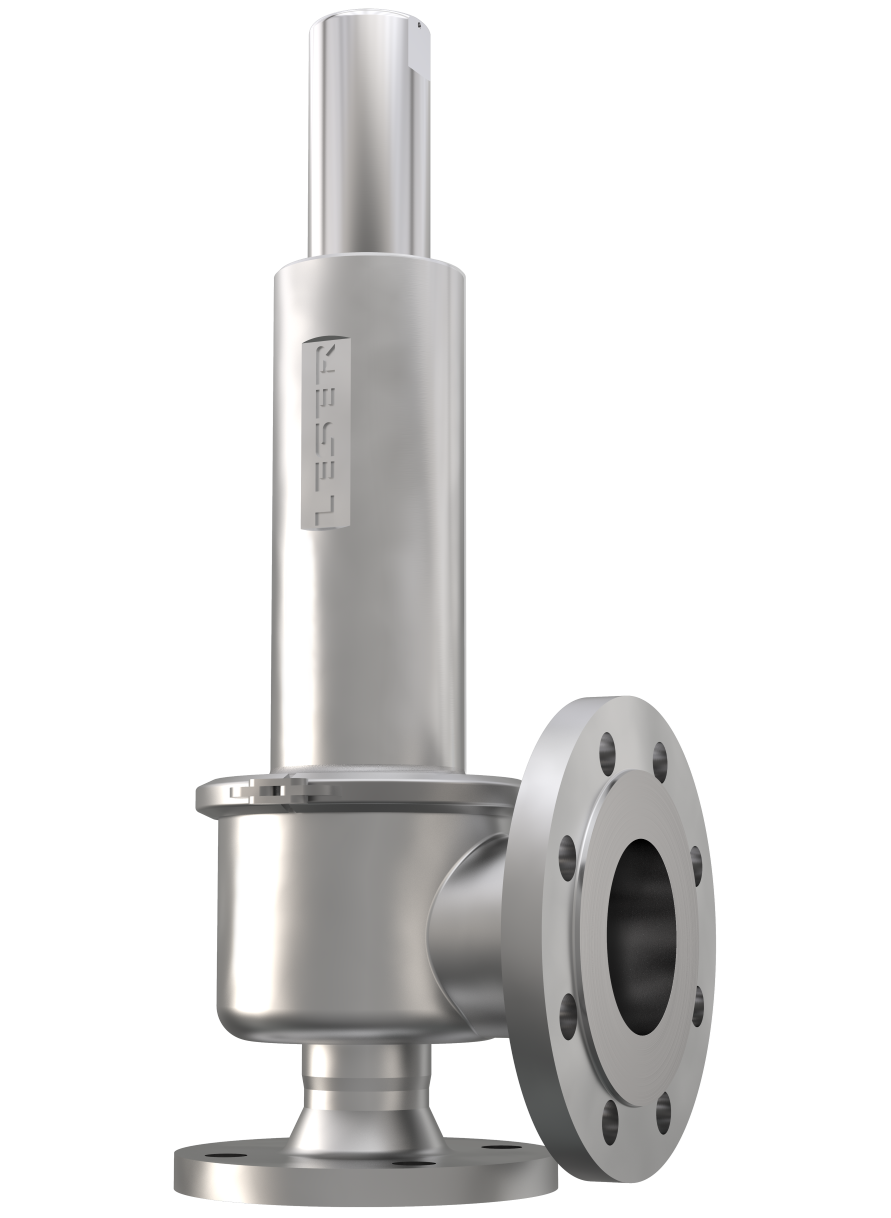

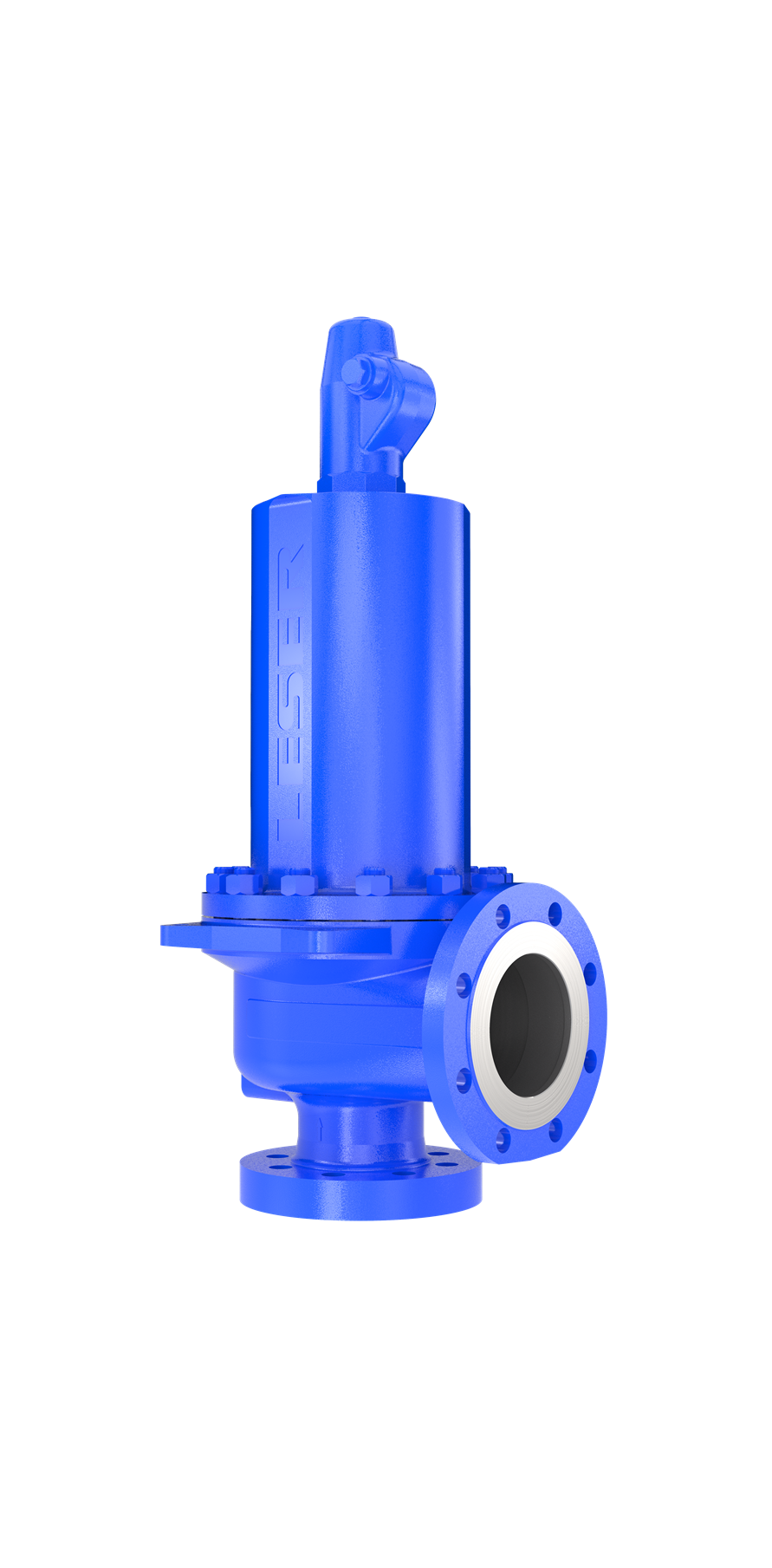

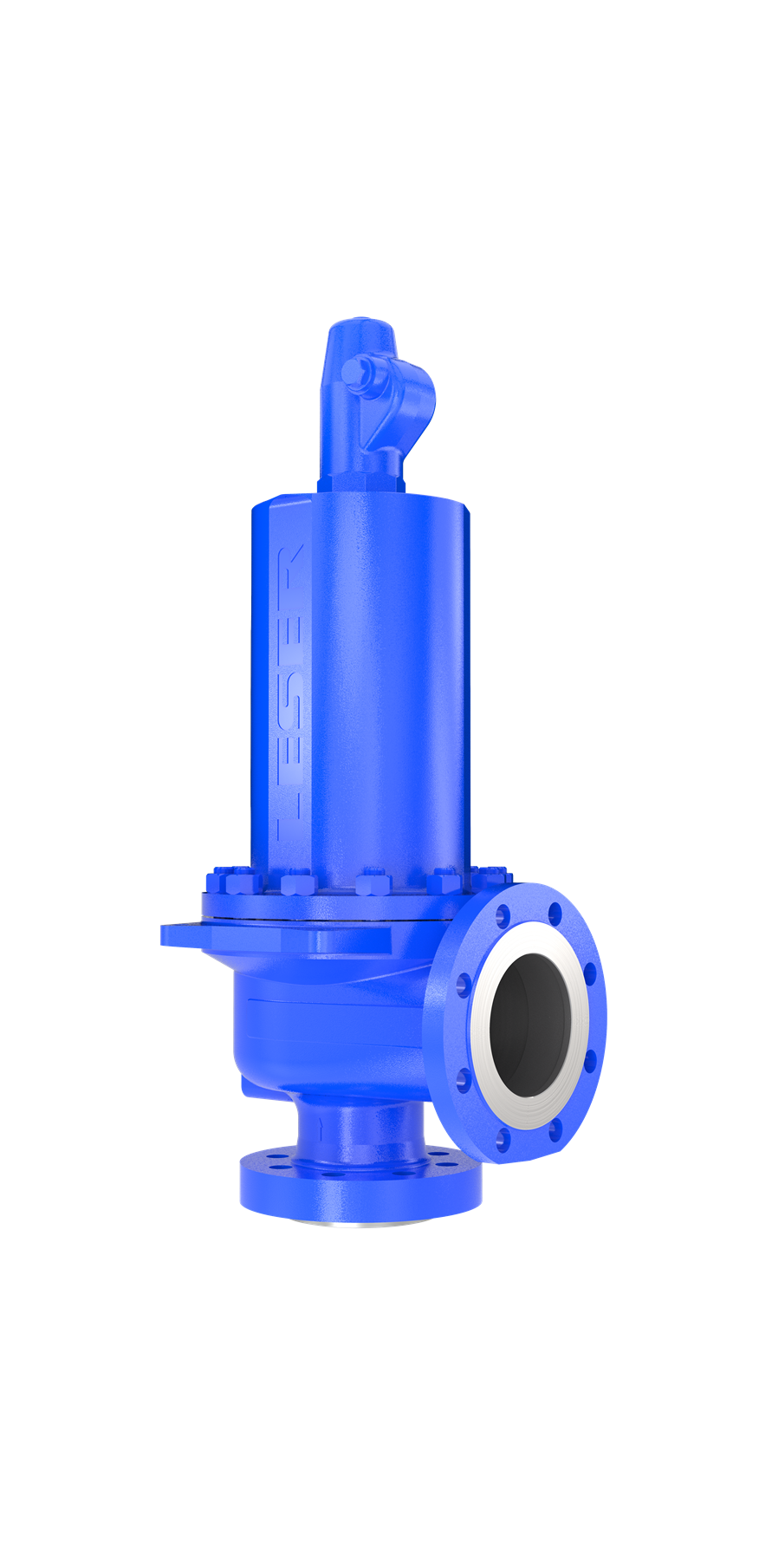

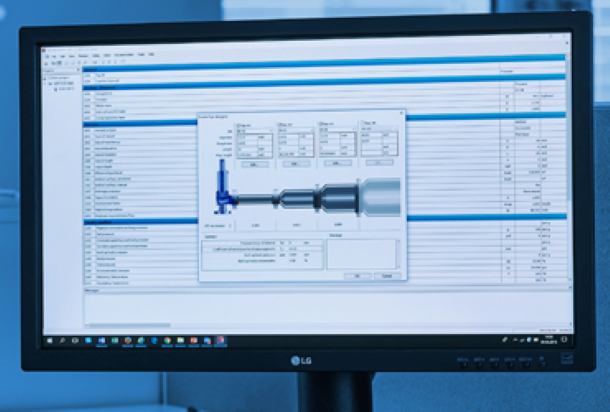

The LESER solutionAs a renowned manufacturer of Safetys valves , it is advantageous to be able to react flexibly to the above-mentioned concerns, i.e. primarily the small installation space, with its portfolio. Being able to change the installation position of Safetys valves is a clear advantage for the compressor designer. He is much more variable in his construction and design options and can also respond more flexibly to special customer specifications. If the progressive modularization of compressors calls for more compact designs, safety valves in different installation positions, for example, can be an answer to the problem, as opposed to the classic upright position. In addition, the spindle guide plays a special role here. The friction

at the guide points must be reduced as far as possible so that the spindle moves easily. Otherwise, a Safetys valve can only be installed in an upright position.

Why LESER Safetys valves ?For a globally active OEM, such as AERZEN, a specialist like LESER , who not only has the knowledge but also the necessary approvals, is an important building block to the

Success. LESER offers a global approval concept through which Safetys valves can be used regardless of location. When ordering Safetys valves , it is basically only necessary to specify the applicable regulations in order to ensure appropriate labeling and material selection. In addition, LESER has tested and approved other installation positions besides the conventional installation situation, standing on the inlet pipe . Thus, for some type n of valves , installation with a horizontal spindle or even suspended installation is permitted, e.g. for the type n 526 and 441. For horizontal installation, attention must be paid to the orientation of the outlet . Fluids , e.g. in the form of condensate, should be able to drain off downwards to avoid back pressures and even corrosion. For upside-down installation, the inverted weight forces are compensated by correction factors.

LESER offers not only Safetys valves with basic documentation and accessories but also other special documentation and options. From "Fugitive Emission Test" with helium up to 3.2 ship class casting and from back pressures up to more than 200 bar-g to high pressure heating jackets for up to 30 bar-g LESER sales engineers develop solutions for customer specific applications as described above for AERZEN.