VDMA reports on the use of safety valves in vaccine production

As part of its reporting on current topics in the industry, the VDMA (German Engineering Federation) has published an article on the topic of "Safety valves in vaccine production". For this purpose, LESER has provided an insight regarding the cooperation with various pharmaceutical manufacturers.

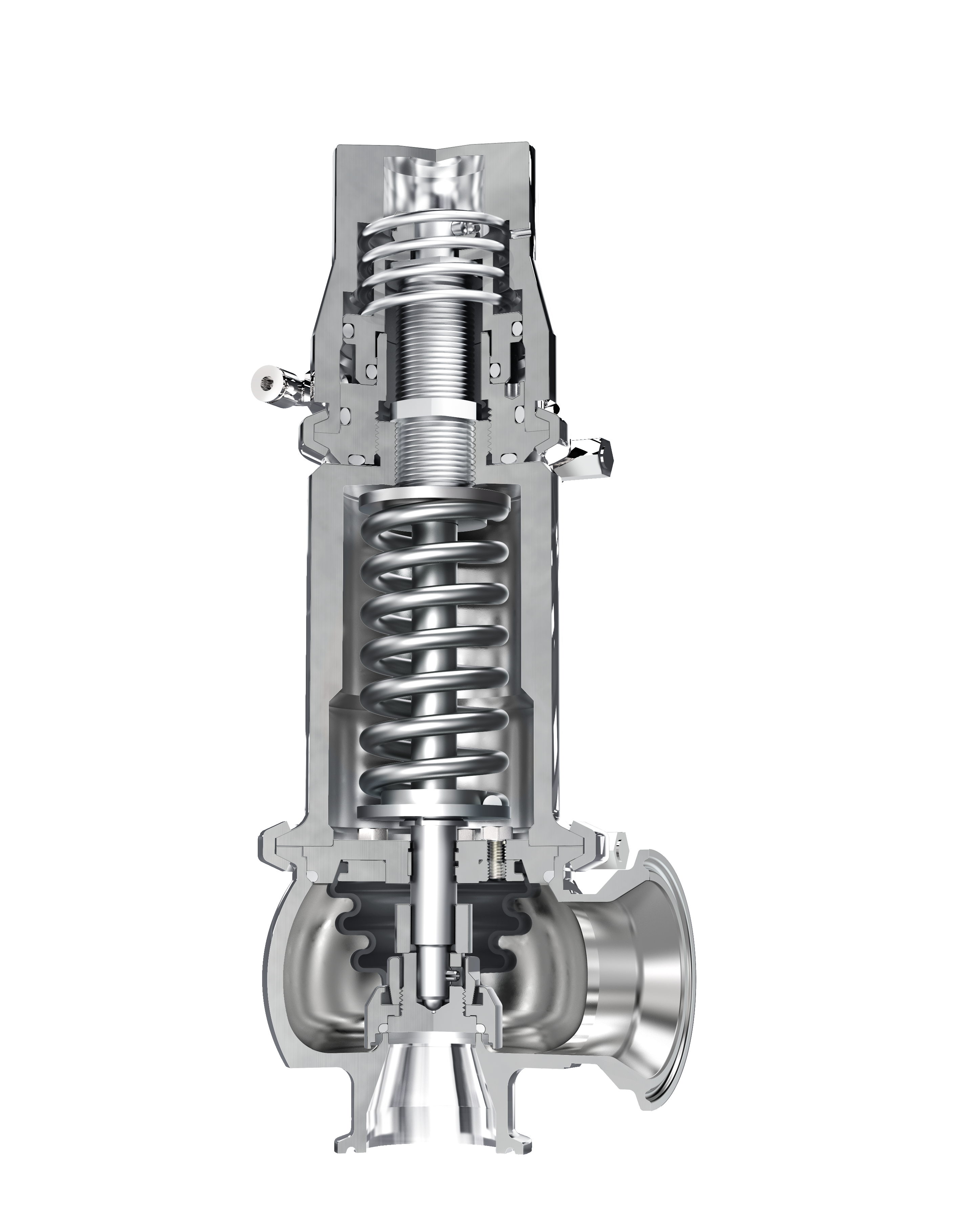

“LESER contributes to the rapid build-up of the necessary production capacities with suitable safety valves for production plants for vaccine production. For LESER, the pharmaceutical industry is an important customer group, so the Clean Service product group was able to provide the right solution with short delivery times right from the start. The safety valves are required in the production plants to protect against impermissible overpressure, prevent damage to the plant and thus ensure the safety of people and the environment.