The production expansion in Hohenwestedt

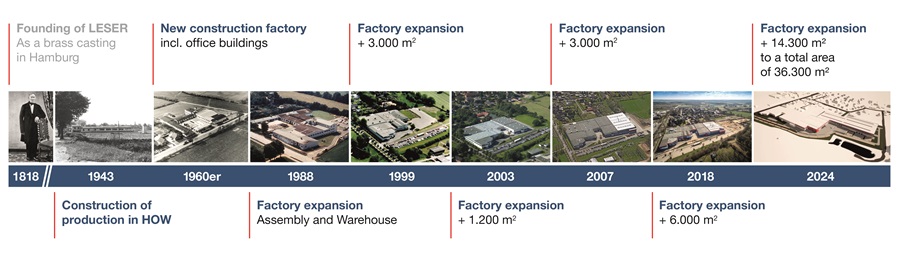

LESER produces 150,000 safety valves annually in Hohenwestedt (Schleswig-Holstein, Germany) and plans to expand the plant by 15,000 m². The last production expansion was completed in 2018. However, the current space capacity is no longer sufficient to meet the growing customer business and the requirements for new technologies and an efficient material flow.

Building construction will begin in 2024, so that the building will be completed in 2025. LESER is investing €41.3 million in this construction project. In addition, further expansion steps are planned up to 2032 as part of the plant structure planning.