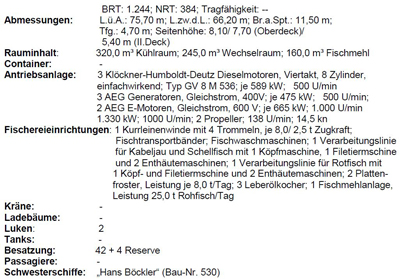

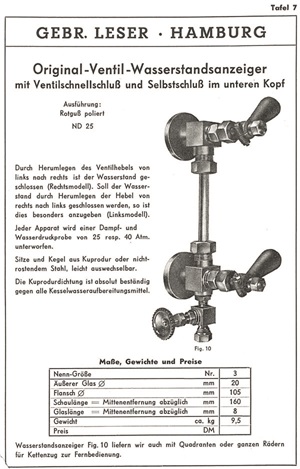

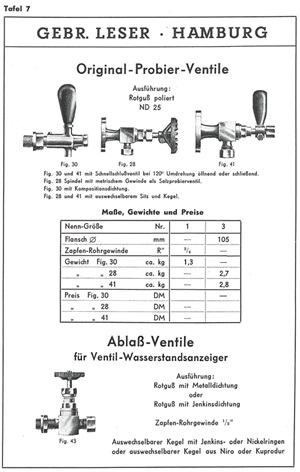

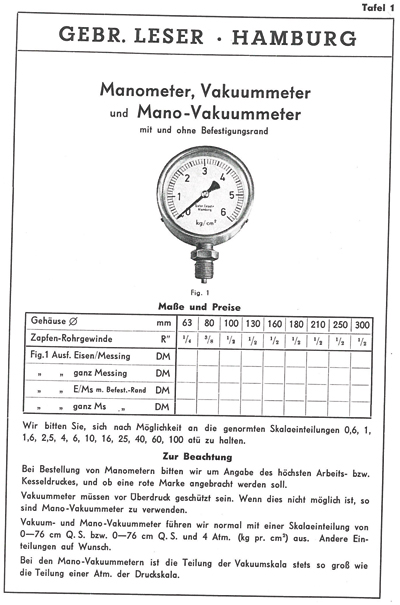

The individual valvetype water level indicator on the left side of the boiler wall is equipped with quick-closing valves (see original sampling valves Fig. 41). The water indicator could be closed and opened by turning the valve lever 120°. A right- and left-hand model was available. To protect the glass tube from external influences, it is equipped with a wire glass protective sleeve.

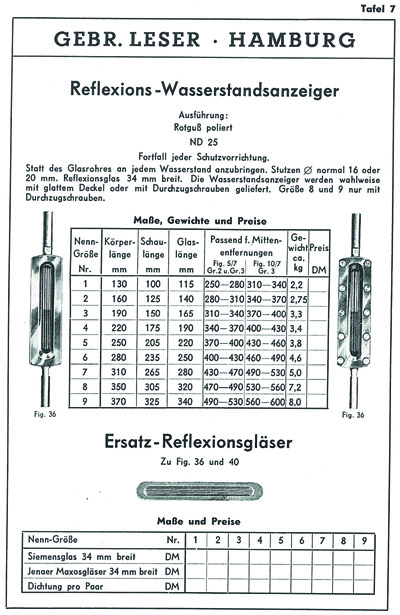

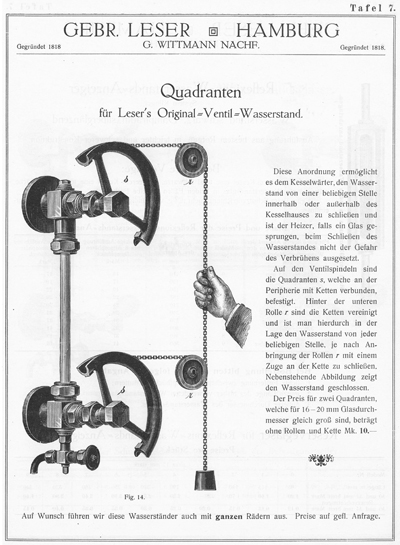

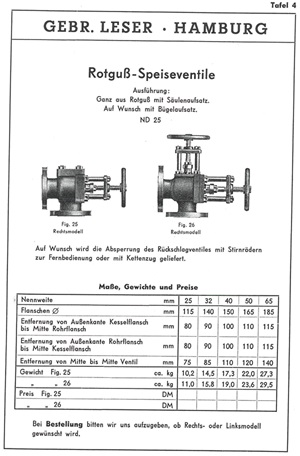

The glass tubes of the central and right water level indicators have been replaced by reflection water level indicator. These indicated a totally black surface for an overfilled boiler and a completely white surface for an empty boiler. For a glass tube, the same colour was displayed in both cases. In addition, no additional protection device was required for the water level indicators. The quick-closing valves have two hand wheels with chain pull instead of the plug key. This configuration allows the boiler operator to close the water level from anywhere inside or outside the boiler house. Moreover, if a glass was broken, the "heater" was not at risk of scalding when closing the water level indicator.

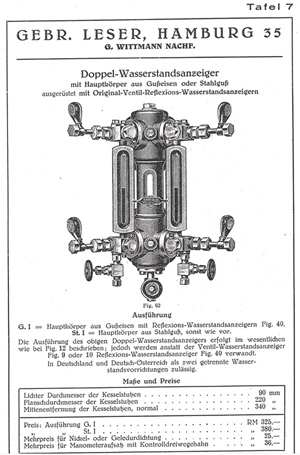

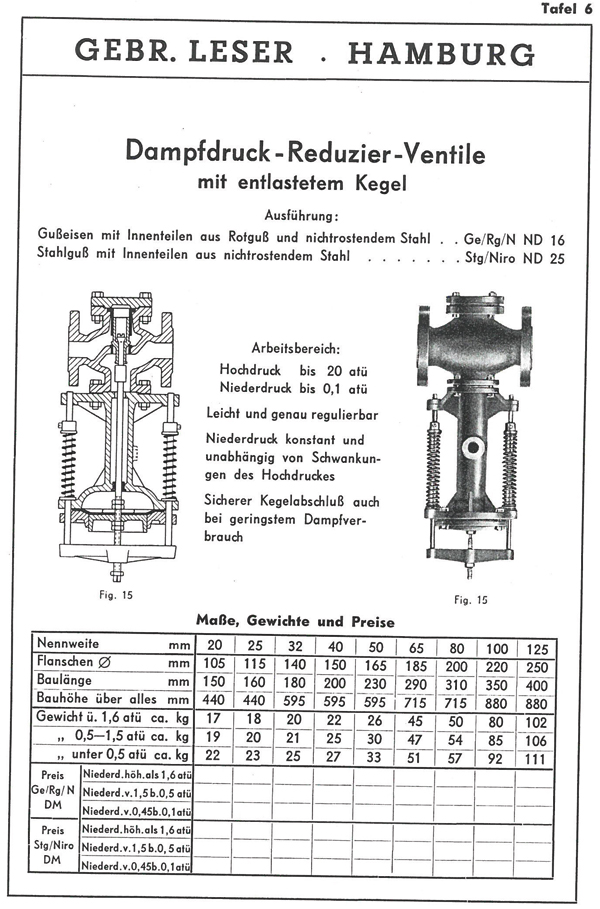

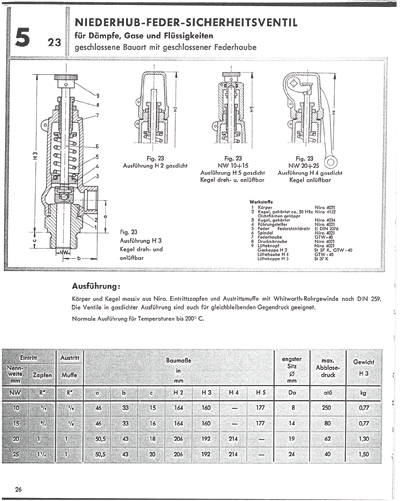

More details on the original valve-type reflective water level indicators, Wired Glass Sleeves and Chain Hoists: