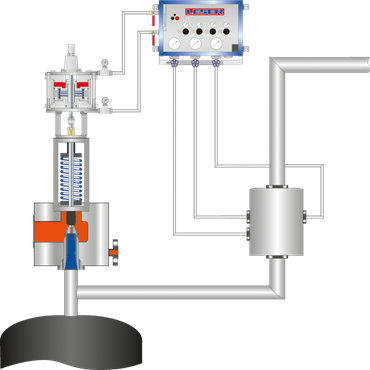

High Efficiency - Supplementary loading system

- Tight to set pressure

- Operating pressures up to 97% of set pressures

- Low loss of medium during blow-off process

| Set pressure |

0.1 - 250 barg | 1.5 - 3626 psig |

|

| Temperature |

-40 - 550 °C | -40 - 1,022 °F |

|

| Capacity | Orifice F- to X | |

| Connections DIN EN 1092 |

DN 25 to DN 400 |

|

| Connections ASME B16.5 |

NPS 3/4 to NPS 16 | |

|

Body material |

Gray cast iron, nodular cast iron, carbon steel , high-temperature carbon steel , stainless cast steel |

Industry / Application

Research center as end user

LESER products

Pneumatic option with high-performance safety valves

Challenge

Protection of a helium plant with extremely low temperatures of -273 °C, high back pressures of 60% and low set pressure of 0.5 bar

Download the High Efficiency - Suplementory Loading System - Catalogue now.