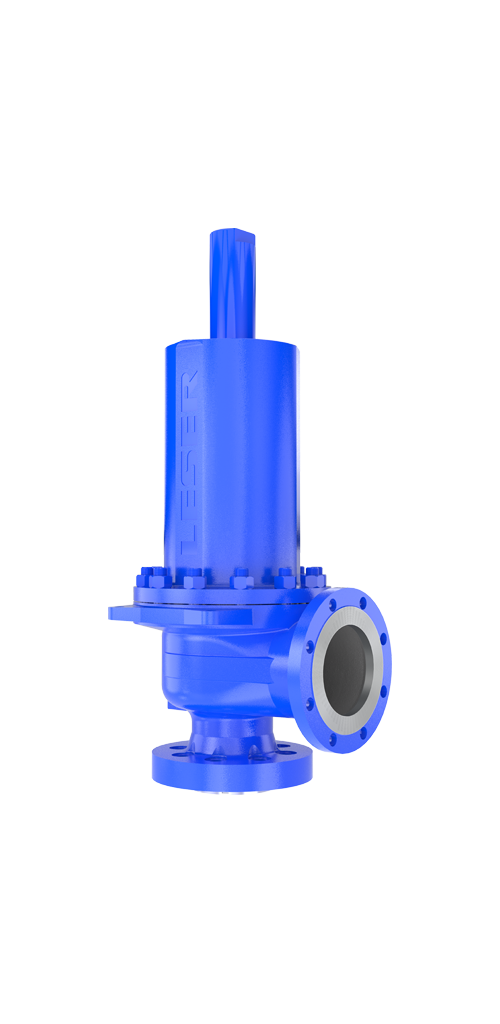

APIType 526

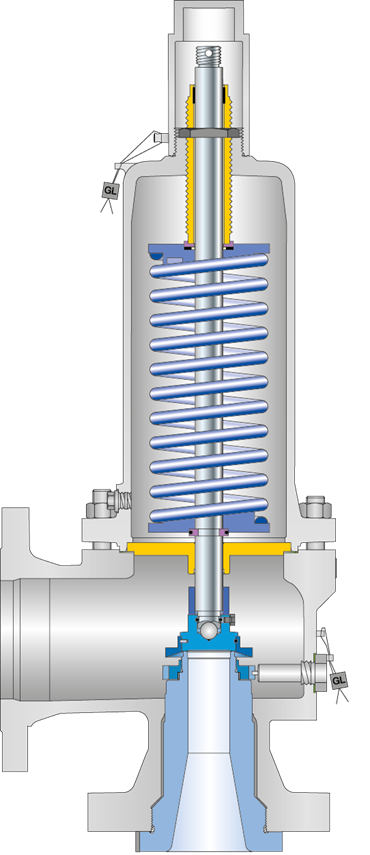

Spring loaded safety valves according to API 526. Technical data

- High alloy materials available in 4 weeks delivery time

- Longer life due to hardened discs, stellited seats and shielded bellows

- LESER Nanotightness exceeds API 527 tightness requirements by 50 %