The challenge

The liquefaction process must be designed efficiently so that the LNG can be offered economically. The necessary cryogenic media temperatures of -161 to-164 °C represent a challenge for the technical design of the individual components in the plant. This also applies in particular to the safety valves , which must function reliably as the final safeguard in the event of overpressure , even at the cryogenic process and Russian ambient temperatures. When implementing the project, Linde expected its suppliers not only to solve the technical requirements, but also to deliver reliably and on time.

The LESER solution

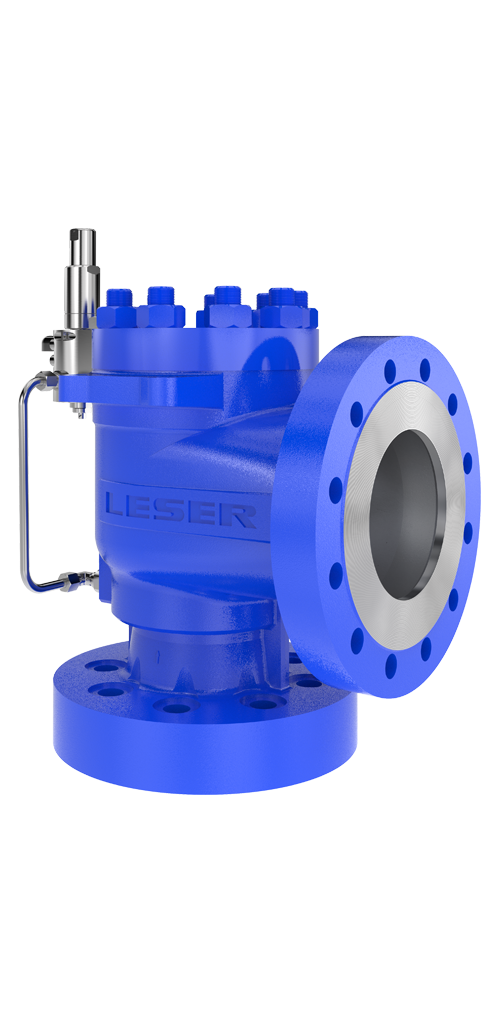

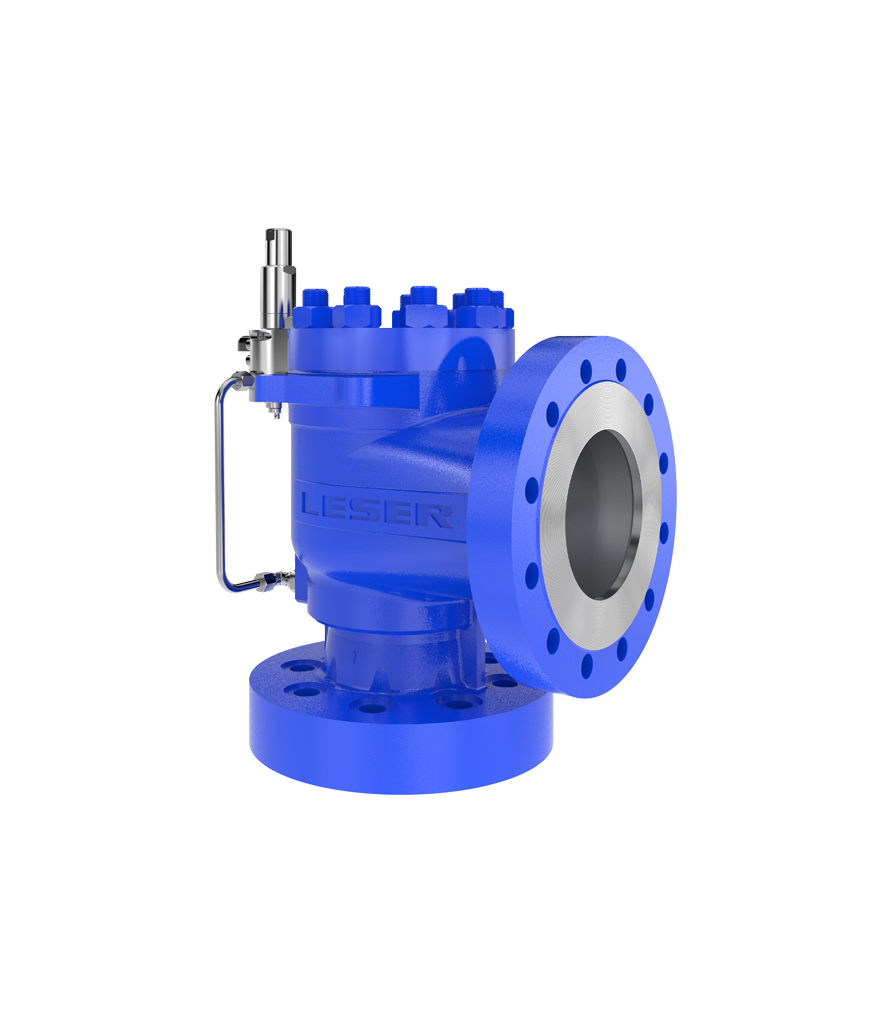

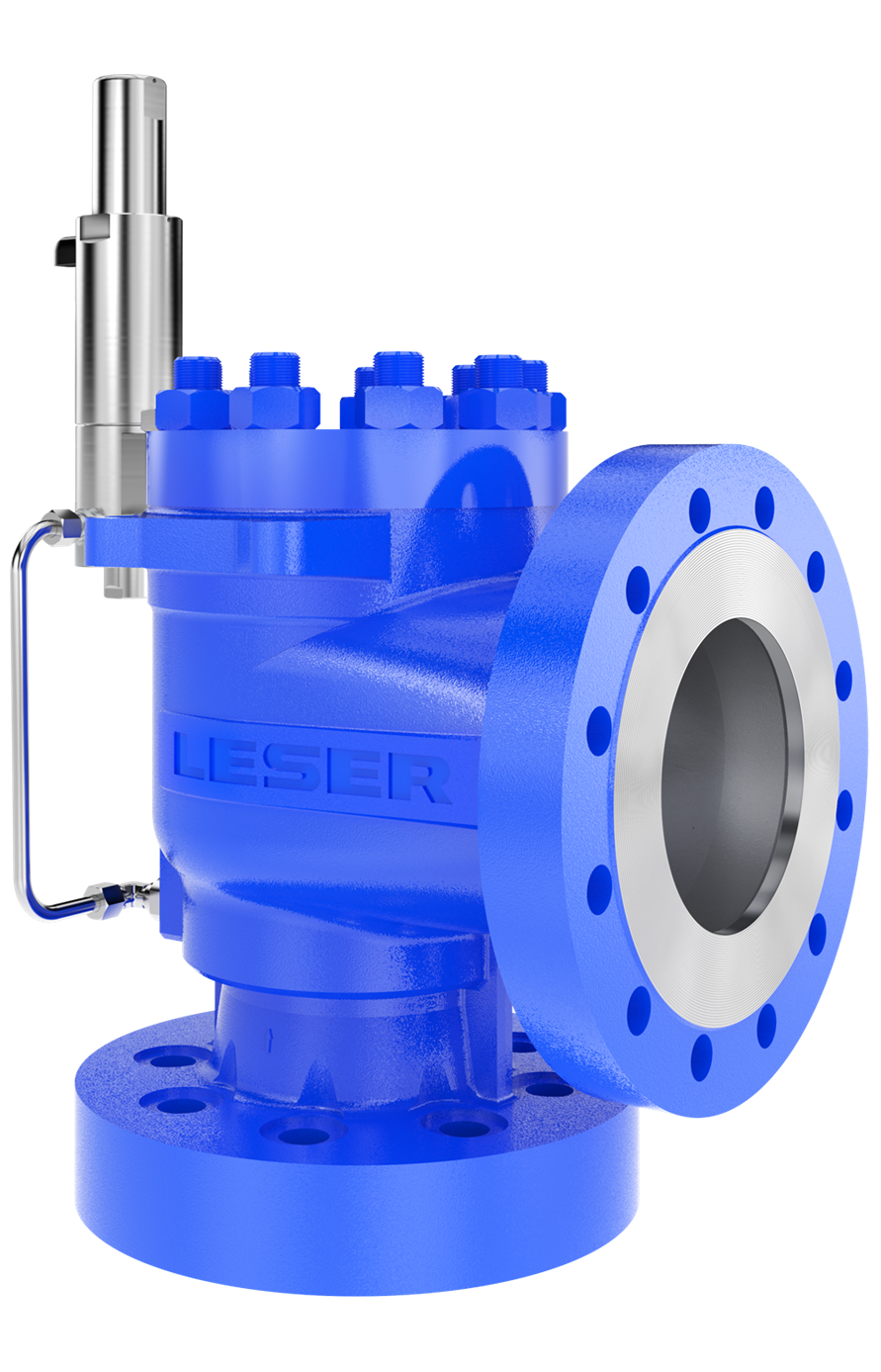

LESER Valvee meet all requirements for use in natural gas liquefaction plants and offer a complete product range. The valves are constructed in a low-maintenance "Durable Design" and can be adapted to the plants through a wide range of options.

The tightness of the Safetys valves was proven under real conditions at media temperatures below -146 °C on LESER's in-house cryo test rig. The precise helium tightness test is based on the DIN EN 13648-1 standard.

Plant efficiency was supported by the use of pilot-operated Safetys valves (POSV) in the relevant areas. In contrast to spring-loaded Safetys valves , they are tight until they respond and thus meet the requirement for a higher operating pressure in relation to the set pressure of the plant. Six POSVs now support the efficiency of LIMUM® technology in the condensing unit.

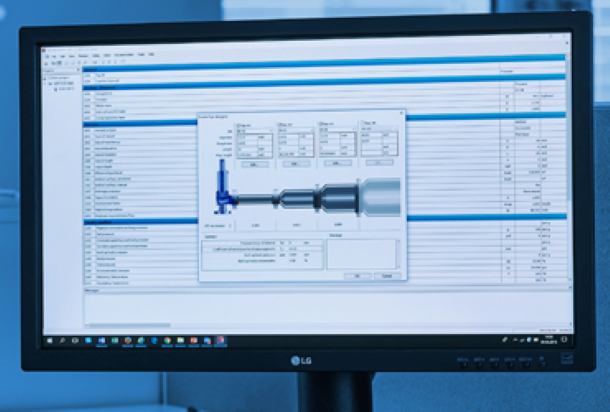

The LESER POSV for LNG is based on the proven design for LPG applications - Liquefied Petroleum Gas, which has been in use for many years as a standardized solution.

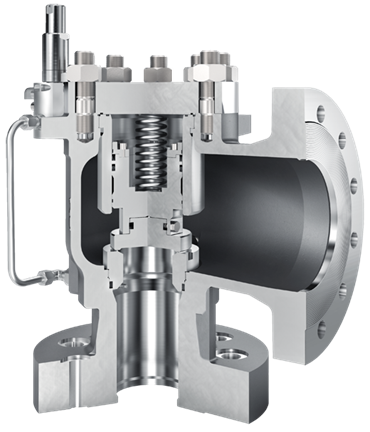

For the LNG low-temperature range, LESER has further developed the design in a modular way so that it can be adapted to the respective project requirements. For example, in the plant in Russia, an evaporator was used and the pilot was thermally decoupled from the main valve to achieve a gaseous media condition in the pilot en. A temperature-resistant PTFE compound for the piston seal in the main valve allows the spring-assisted lip seal to be used at operating temperatures down to -162 °C. The special nozzle design does not require a soft seal in the wetted inlet area. The piloting valve is equipped with a low-temperature resistant soft seal in the Pop Action and

Modulate Action available for different requirements.

LESER 's project department supported Linde from the first FEED phase to the commissioning of the project. The "Project Assembly" manufacturing segment is specially designed to meet the requirements of projects and offers optimum conditions for customer acceptance tests.

Why did the customer choose LESER products ?

Linde relies on LESER 's know-how in the cryogenic market, e.g. also in projects with temperatures as low as -269 °C for liquid helium applications. The company has been working with LESER in the field of technical gases for many years and knows its capacities very well. The joint experience in project execution of air separation plants and the complete LNG product range, especially the modular Cryo-POSV in Pop Action Design , were important for Linde.