Steam Whistles and Injectors

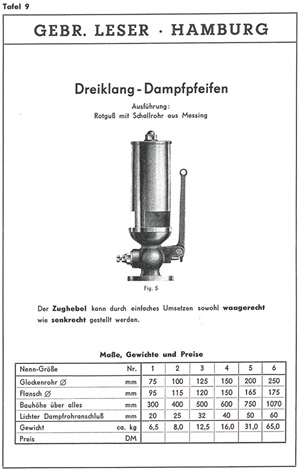

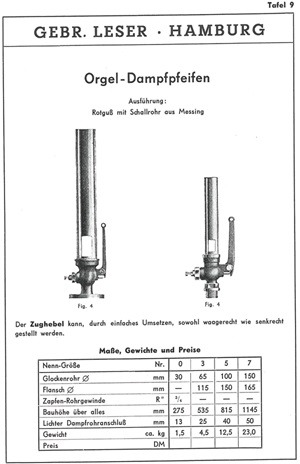

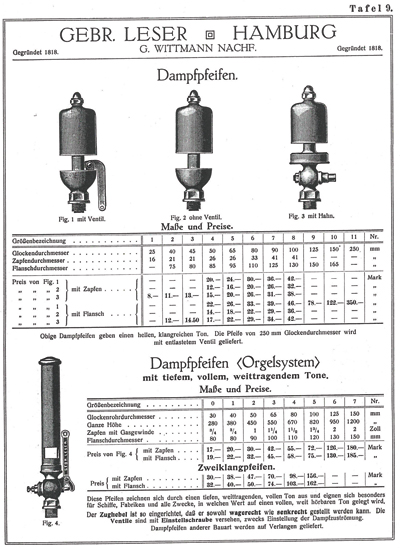

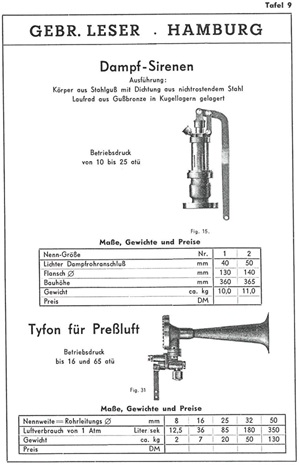

Steam whistles were not only signaling instruments but also prestige objects; especially on the small ships in the port of Hamburg. There were organ pipes, two-tone pipes and triad pipes. Organ pipes are recognizable by the fact that it was possible to see through the sound hole. The triad pipes were carefully and elegantly adjusted.

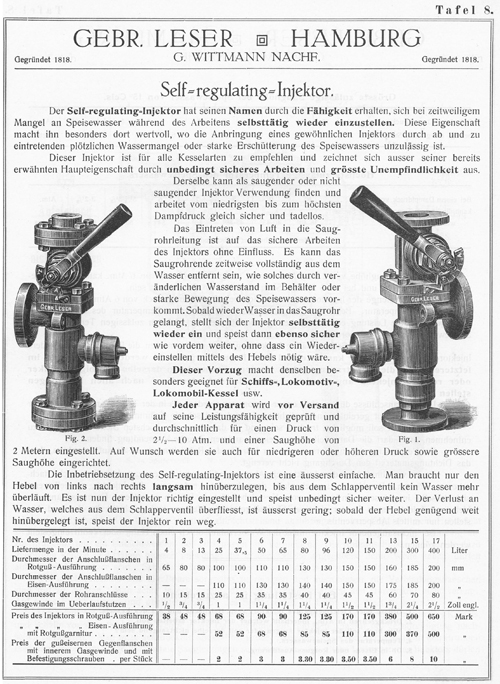

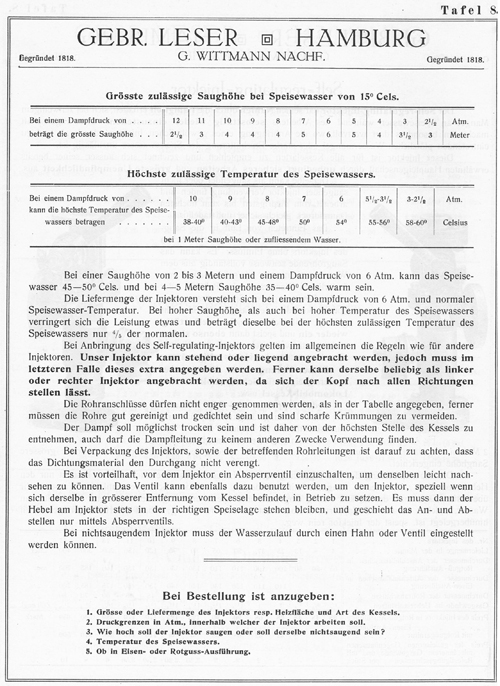

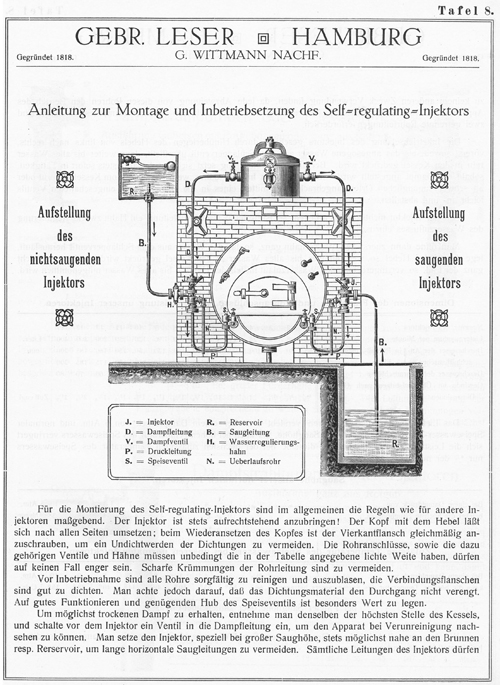

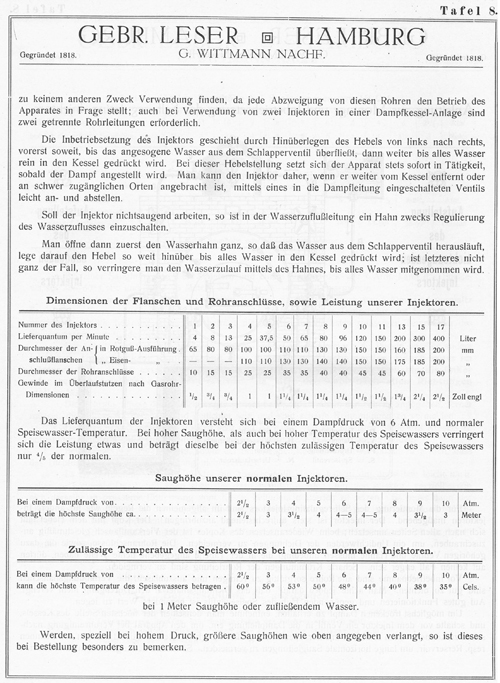

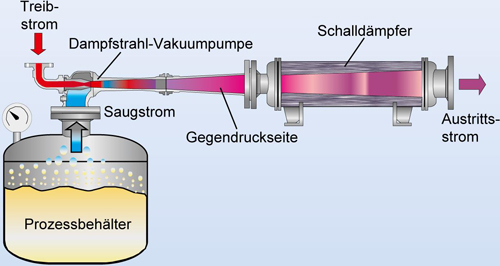

Injectors were used to suck water in with the help of the boiler's own steam pressure and then feed it to the boiler as supply water under increased pressure. This fitting has occupied generations of technicians and many different inventions have been developed.