Miniature Valves

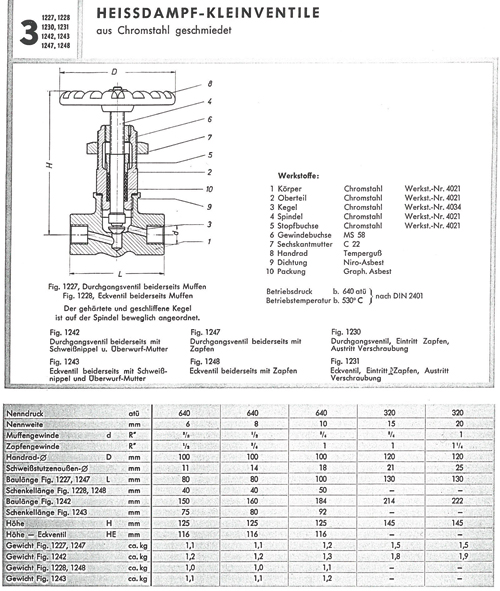

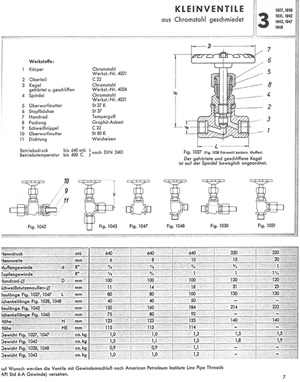

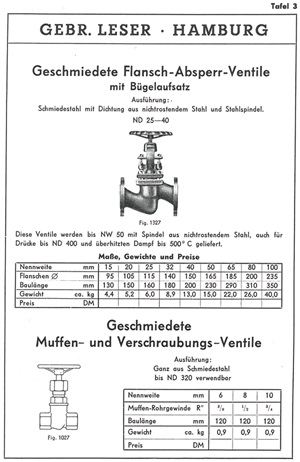

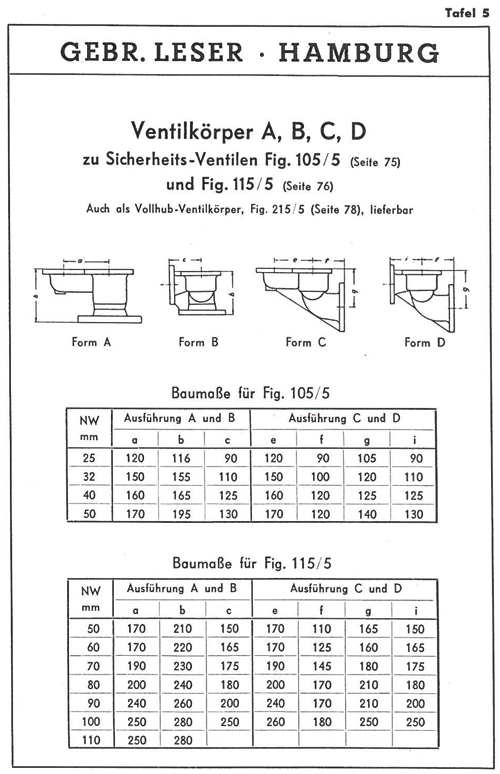

Until the 70s, the miniature hot steam forged valves were manufactured in countless variants.

On exhibition here are two miniature valves with R1/2" male thread and R3/4" female thread. A male thread describes the external thread and a female thread the internal thread.