LESER Safety Valves for hydrogen applications

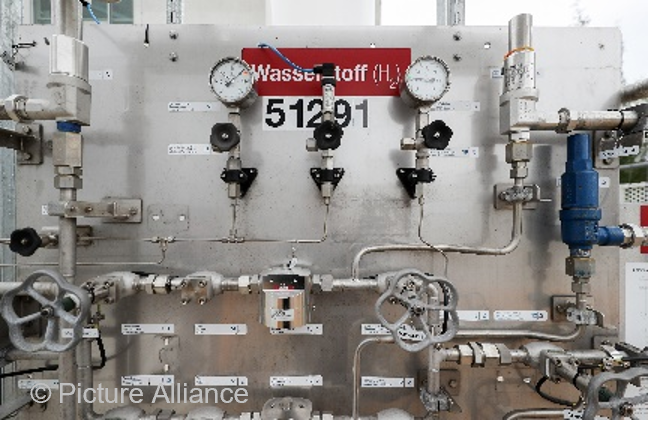

Already today, more than 600 billion cubic meters of hydrogen are produced each year worldwide for the process industry. Hydrogen is a basic material in many industries, e.g. in refineries, in ammonia production or other chemical processes. Hydrogen is produced by chemical processes or electrolysis processes using electrical energy.

In addition to these needs, the technology for using hydrogen as an energy source in combustion engines or via fuel cells is now also ready to replace petroleum products in the future.

The advantages of hydrogen as an energy carrier are among them:

- Neutral CO2-footprint: Hydrogen produced from renewable energies is a CO2-neutral energy carrier and basic material.

- Flexible energy storage: Hydrogen produced from renewable energies can be stored in liquid or gaseous form in tanks and caverns. It is distributed over the area using mobile tanks and existing gas pipelines.

- Power to X: Hydrogen can be used flexibly as an energy supplier in fuel cells, fuel in combustion engines and as a coke substitute in steel production. With the addition of CO2, it can also be used as a fuel and combustible.

.png?h=245&w=126&hash=D237E82289388C6E729F2B7843FC1B4C)

.png?h=199&w=143&hash=8B61F390F6CC504ECE58A43DE31A6E25)