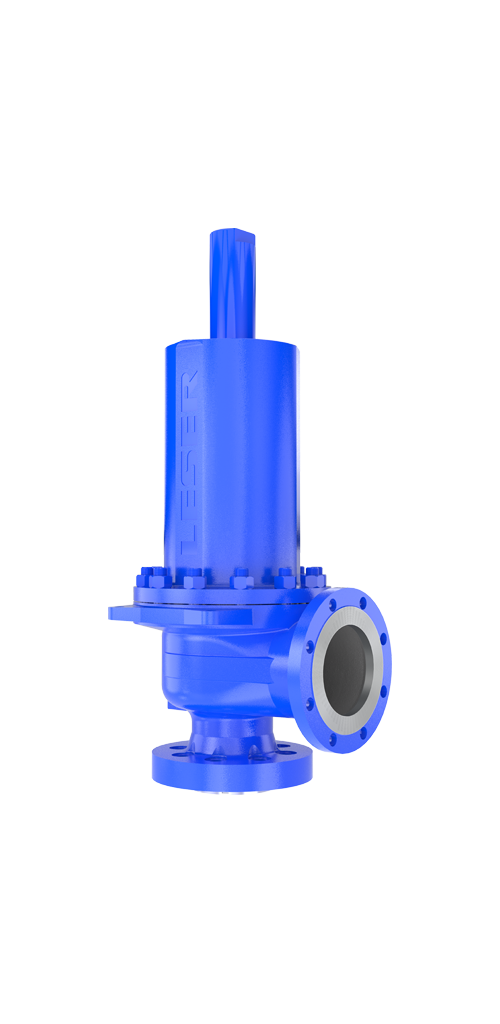

LESER's solution against corrosion

In the last 10 years LESER has installed more than 1800 Safetys valves in urea plants in almost all countries of the world.

Of these 1800, more than 320 are equipped with the LESER Steam Flushing System , which prevents clogging of the discharge bladder line and condensation and erosion corrosion in the seat area .

More than 70 Safetys valves are designed with a standardized 3J4 block body design and LESER flushing system with the following advantages:

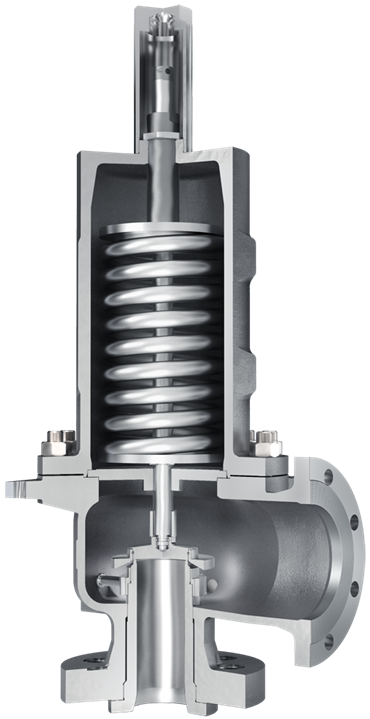

- Material of all wetted parts can be in high corrosion resistant composition

- Constant temperature of the nozzle, higher than the condensation temperature of the carbamate solution, to avoid negative corrosion effects and material structure effects of the sealing surface.

- Metal-to-metal sealing with LESER nanotightness process for sealing finishn with roughness and flatness in the measuring range of 100 nm.

- 360° flushing of the main valve body to prevent crystallization in the event of a blowdown situation

- A steam supply point is required for LESER purging , even if a Heating jacket is pre-installed to heat the outer area of the block body with minimal steam consumption .

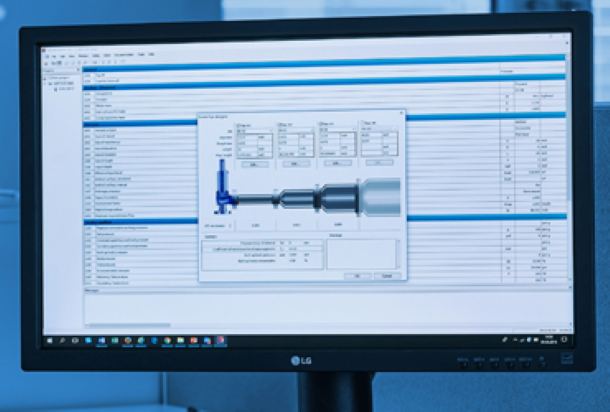

And the synthesis sections of already four lines in urea plants are equipped with the LESER auxiliary loading system , which allows these plants to operate the synthesis pressure very close to the target pressure, resulting in higher conversion rates and 75% lower emissions in case of a blowdown situation.